Research on the Effect of LED Supplementary Light on the Yield Increasing Effect of Hydroponic Lettuce and Pakchoi in Greenhouse in Winter

[Abstract] The winter in Shanghai often encounters low temperature and low sunshine, and the growth of hydroponic leafy vegetables in the greenhouse is slow and the production cycle is long, which cannot meet the market supply demand. In recent years, LED plant supplementary lights have begun to be used in greenhouse cultivation and production, to a certain extent, to make up for the defect that the daily accumulated light in the greenhouse cannot meet the needs of crop growth when the natural light is insufficient. In the experiment, two kinds of LED supplementary lights with different light quality were installed in the greenhouse to carry out the exploration experiment of increasing the production of hydroponic lettuce and green stem in winter. The results showed that the two kinds of LED lights can significantly increase the fresh weight per plant of pakchoi and lettuce. The yield-increasing effect of pakchoi is mainly reflected in the improvement of overall sensory quality such as leaf enlargement and thickening, and the yield-increasing effect of lettuce is mainly reflected in the increase of the number of leaves and dry matter content.

Light is an indispensable part of plant growth. In recent years, LED lights have been widely used in cultivation and production in a greenhouse environment due to their high photoelectric conversion rate, customizable spectrum, and long service life [1]. In foreign countries, due to the early start of related research and the mature supporting system, many large-scale flower, fruit and vegetable production have relatively complete light supplement strategies. The accumulation of a large amount of actual production data also allows producers to clearly predict the effect of increasing production. At the same time, the return after using the LED supplement light system is evaluated [2]. However, most of the current domestic research on supplemental light is biased towards small-scale light quality and spectral optimization, and lacks supplementary light strategies that can be used in actual production[3]. Many domestic producers will directly use existing foreign supplementary lighting solutions when applying supplemental lighting technology to production, regardless of the climatic conditions of the production area, the types of vegetables produced, and the conditions of facilities and equipment. In addition, the high cost of supplemental light equipment and high energy consumption often result in a huge gap between the actual crop yield and economic return and the expected effect. Such a current situation is not conducive to the development and promotion of the technology of supplementing light and increasing production in the country. Therefore, it is an urgent need to reasonably put mature LED supplementary light products into actual domestic production environments, optimize use strategies, and accumulate relevant data.

Winter is the season when fresh leafy vegetables are in great demand. Greenhouses can provide a more suitable environment for leafy vegetables growth in winter than outdoor farming fields. However, an article pointed out that some aging or poorly clean greenhouses have a light transmittance of less than 50% in winter.. In addition, long-term rainy weather is also prone to occur in winter, which makes the greenhouse in a low-temperature and low-light environment, which affects the normal growth of plants. Light has become a limiting factor for the growth of vegetables in winter [4]. The Green Cube that has been put into actual production is used in the experiment. The shallow liquid flow leafy vegetable planting system is matched with Signify (China) Investment Co., Ltd.’s two LED top light modules with different blue light ratios. Planting lettuce and pakchoi, which are two leafy vegetables with greater market demand, aims to study the actual increase in the production of hydroponic leaf vegetables by LED lighting in the winter greenhouse.

Materials and Methods

Materials used for test

The test materials used in the experiment were lettuce and packchoi vegetables. Lettuce variety, Green Leaf Lettuce, comes from Beijing Dingfeng Modern Agriculture Development Co., Ltd., and pakchoi variety, Brilliant Green, comes from Horticulture Institute of Shanghai Academy of Agricultural Sciences.

Experimental method

The experiment was conducted in the Wenluo type glass greenhouse of Sunqiao base of Shanghai green cube Agricultural Development Co., Ltd. from November 2019 to February 2020. A total of two rounds of repeated experiments were conducted. The first round of the experiment was at the end of 2019, and the second round was at the beginning of 2020. After sowing, the experimental materials were placed in the artificial light climate room for seedling raising, and the tide irrigation was used. During the seedling raising period, the general nutrient solution of hydroponic vegetables with EC of 1.5 and pH of 5.5 was used for irrigation. After the seedlings grew to 3 leaves and 1 heart stage, they were planted on the green cube track type shallow flow leafy vegetable planting bed. After planting, the shallow flow nutrient solution circulation system used EC 2 and pH 6 nutrient solution for daily irrigation. The irrigation frequency was 10 min with water supply and 20 min with water supply stopped. The control group (no light supplement) and the treatment group (LED light supplement) were set in the experiment. CK was planted in glass greenhouse without light supplement. LB: drw-lb Ho (200W) was used to supplement light after planting in glass greenhouse. The light flux density (PPFD) on the surface of hydroponic vegetable canopy was about 140 μmol/(㎡·S). MB: after planting in the glass greenhouse, the drw-lb (200W) was used to supplement the light, and the PPFD was about 140 μmol/(㎡·S).

The first round of experimental planting date is November 8, 2019, and the planting date is November 25, 2019. The test group’s light supplement time is 6:30-17:00; the second round of experimental planting date is December 30, 2019 Day, the planting date is January 17, 2020, and the supplement time of the experimental group is 4:00-17:00

In the sunny weather in winter, the greenhouse will open the sunroof, side film and fan for daily ventilation from 6:00-17:00. When the temperature is low at night, the greenhouse will close the skylight, side roll film and fan at 17:00-6:00 (the next day), and open the thermal insulation curtain in the greenhouse for night heat preservation.

Data Collection

The plant height, number of leaves, and fresh weight per plant were obtained after harvesting the aboveground parts of Qingjingcai and lettuce. After measuring the fresh weight, it was placed in an oven and dried at 75℃ for 72 h. After the end, the dry weight was determined. The temperature in the greenhouse and Photosynthetic Photon Flux Density (PPFD, Photosynthetic Photon Flux Density) are collected and recorded every 5 min by the temperature sensor (RS-GZ-N01-2) and the photosynthetically active radiation sensor (GLZ-C-G).

Data Analysis

Calculate the light use efficiency (LUE, Light Use Efficiency) according to the following formula:

LUE (g/mol) = vegetable yield per unit area/the total cumulative amount of light obtained by vegetables per unit area from planting to harvest

Calculate the dry matter content according to the following formula:

Dry matter content (%) = dry weight per plant/fresh weight per plant x 100%

Use Excel2016 and IBM SPSS Statistics 20 to analyze the data in the experiment and analyze the significance of the difference.

Materials and Methods

Light and Temperature

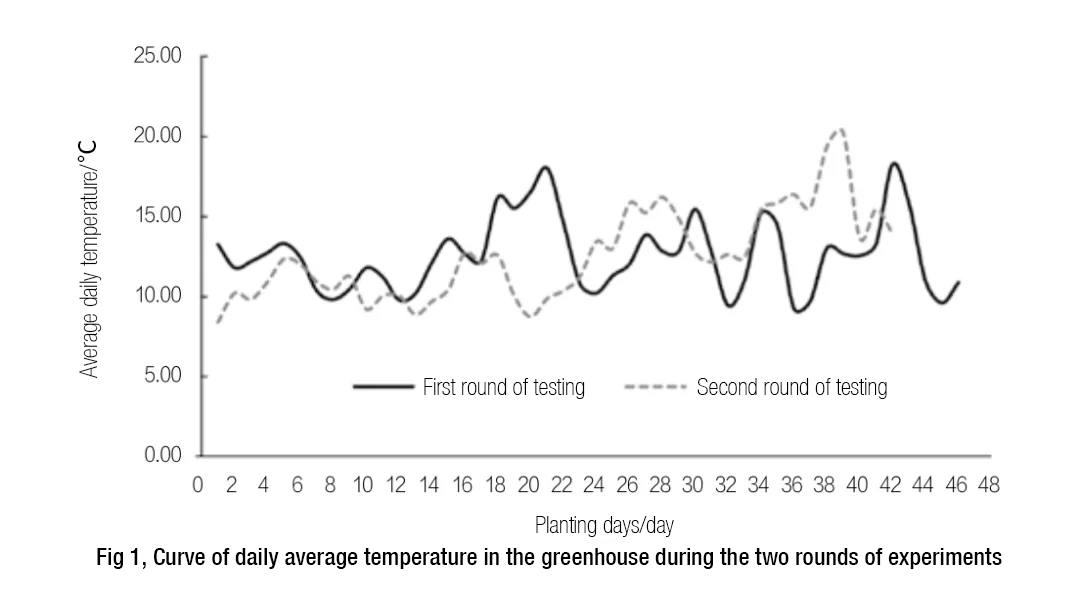

The first round of experiment took 46 days from planting to harvest, and the second round took 42 days from planting to harvest. During the first round of experiment, the daily average temperature in the greenhouse was mostly in the range of 10-18 ℃; during the second round of experiment, the fluctuation of the daily average temperature in the greenhouse was more severe than that during the first round of experiment, with the lowest daily average temperature of 8.39 ℃ and the highest daily average temperature of 20.23 ℃. The daily average temperature showed an overall upward trend during the growth process (Fig. 1).

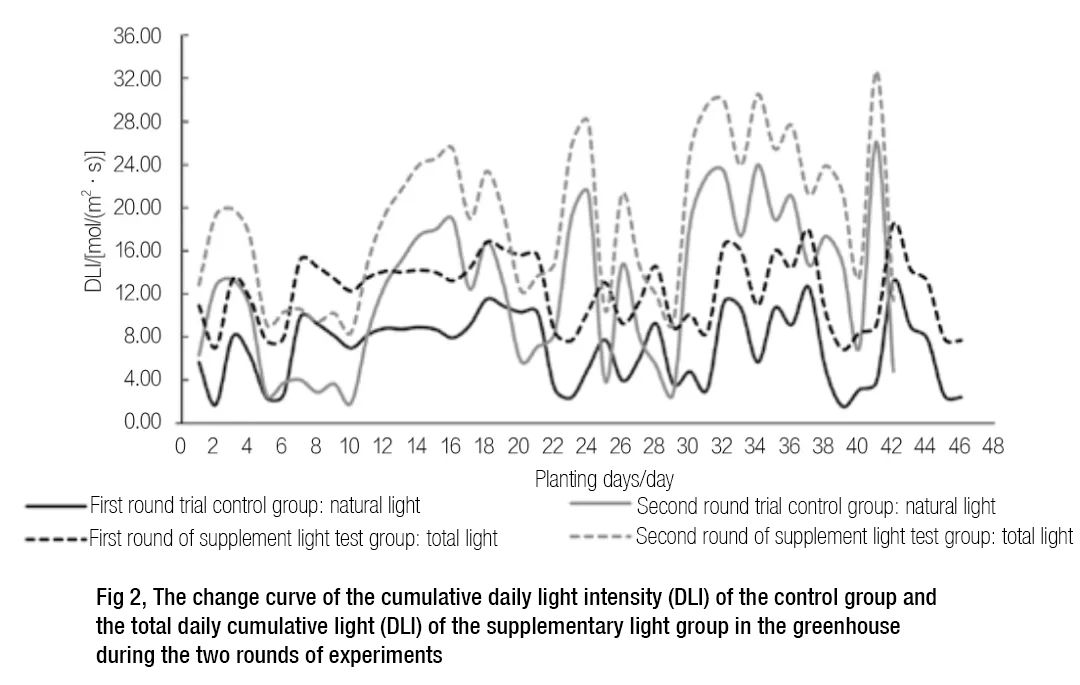

During the first round of experiment, the daily light integral (DLI) in greenhouse fluctuated less than 14 mol/(㎡·D). During the second round of experiment, the daily cumulative amount of natural light in greenhouse showed an overall upward trend, which were higher than 8 mol/(㎡·D), and the maximum value appeared on February 27, 2020, which was 26.1 mol/(㎡·D). The change of daily cumulative amount of natural light in greenhouse during the second round of experiment was larger than that during the first round of experiment (Fig. 2). During the first round of experiment, the total daily cumulative light amount (the sum of natural light DLI and led supplementary light DLI) of the supplementary light group was higher than 8 mol/(㎡·D) most of the time. During the second round of the experiment, the total daily accumulated light amount of the supplementary light group was more than 10 mol/(㎡·D) most of the time. The total accumulated amount of supplementary light in the second round was 31.75 mol/㎡ more than that in the first round.

Leafy Vegetable Yield and Light Energy Utilization Efficiency

●First round of test results

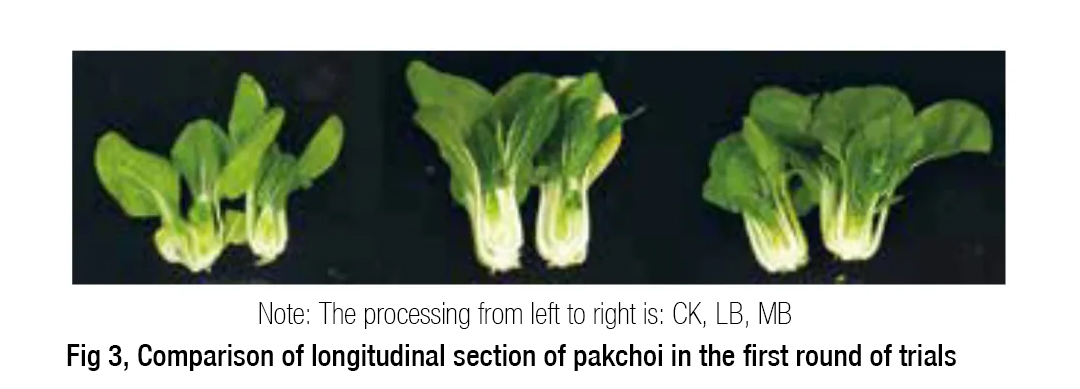

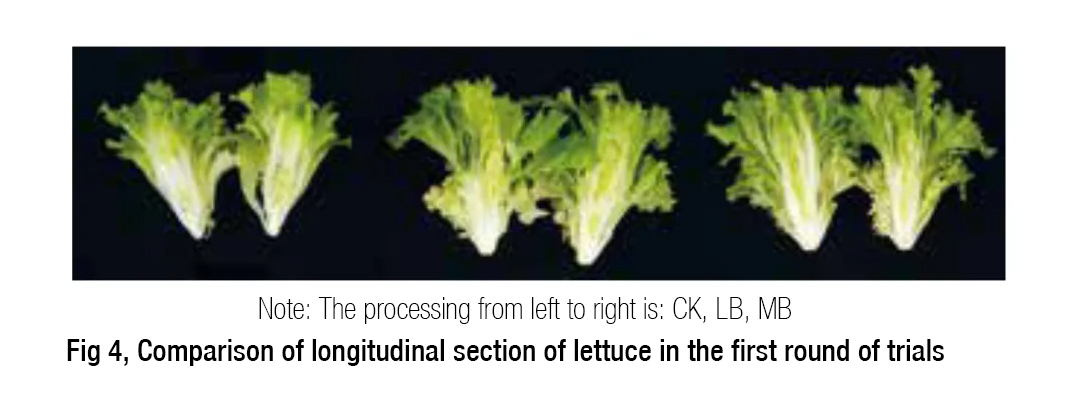

It can be seen from Fig. 3 that the LED-supplemented pakchoi grows better, the plant shape is more compact, and the leaves are larger and thicker than the non-supplemented CK. The LB and MB pakchoi leaves are brighter and darker green than CK. It can be seen from Fig. 4 that the lettuce with LED supplement light grows better than the CK without supplement light, the number of leaves is higher, and the plant shape is fuller.

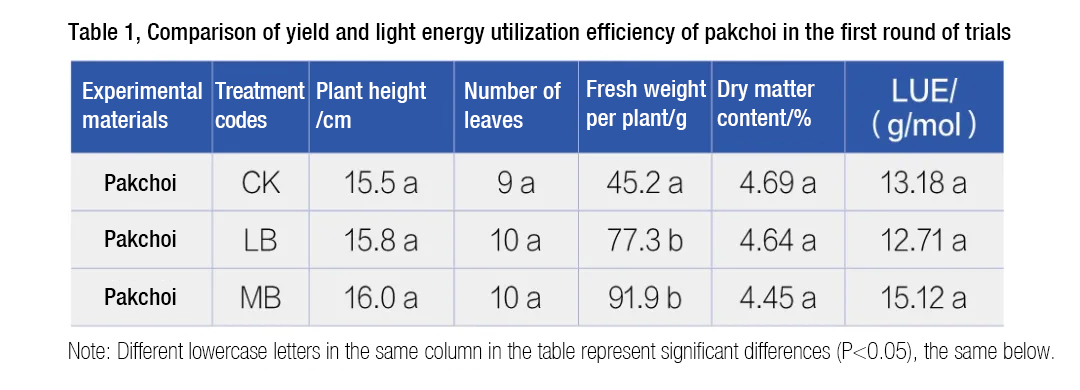

It can be seen from Table 1 that there is no significant difference in plant height, leaf number, dry matter content and light energy utilization efficiency of pakchoi treated with CK, LB and MB, but the fresh weight of pakchoi treated with LB and MB is significantly higher than that of CK; There was no significant difference in fresh weight per plant between the two LED grow lights with different blue light ratios in the treatment of LB and MB.

It can be seen from table 2 that the plant height of lettuce in LB treatment was significantly higher than that in CK treatment, but there was no significant difference between LB treatment and MB treatment. There were significant differences in the number of leaves among the three treatments, and the number of leaves in MB treatment was the highest, which was 27. The fresh weight per plant of LB treatment was the highest, which was 101g. There was also significant difference between the two groups. There was no significant difference in dry matter content between CK and LB treatments. The content of MB was 4.24% higher than CK and LB treatments. There were significant differences in the light use efficiency among the three treatments. The highest light use efficiency was in LB treatment, which was 13.23 g/mol, and the lowest was in CK treatment, which was 10.72 g/mol.

●Second round of test results

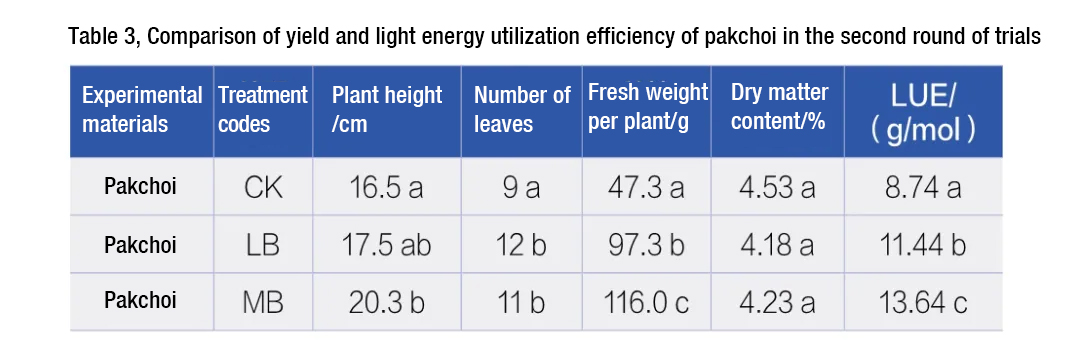

It can be seen from Table 3 that the plant height of Pakchoi treated with MB was significantly higher than that of CK, and there was no significant difference between it and LB treatment. The number of leaves of Pakchoi treated with LB and MB was significantly higher than that with CK, but there was no significant difference between the two groups of supplementary light treatments. There were significant differences in the fresh weight per plant among the three treatments. The fresh weight per plant in CK was the lowest at 47 g, and the MB treatment was the highest at 116 g. There was no significant difference in the dry matter content between the three treatments. There are significant differences in light energy utilization efficiency. CK is low at 8.74 g/mol, and MB treatment is the highest at 13.64 g/mol.

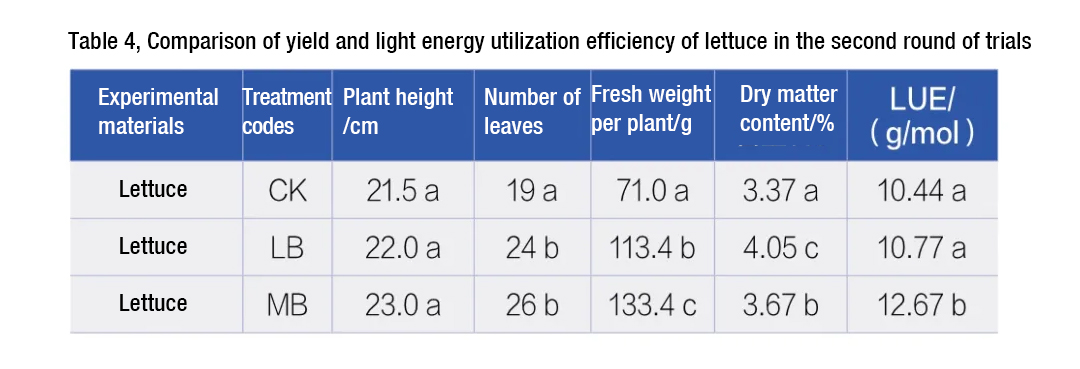

It can be seen from Table 4 that there was no significant difference in plant height of lettuce among the three treatments. The number of leaves in LB and MB treatments was significantly higher than that in CK. Among them, the number of MB leaves was the highest at 26. There was no significant difference in the number of leaves between LB and MB treatments. The fresh weight per plant of the two groups of supplemental light treatments was significantly higher than that of CK, and the fresh weight per plant was the highest in MB treatment, which was 133g. There were also significant differences between LB and MB treatments. There were significant differences in the dry matter content among the three treatments, and the dry matter content of the LB treatment was the highest, which was 4.05%. The light energy utilization efficiency of MB treatment is significantly higher than that of CK and LB treatment, which is 12.67 g/mol.

During the second round of experiment, the total DLI of the supplementary light group was much higher than the DLI during the same number of colonization days during the first round of experiment (Figure 1-2), and the supplementary light time of the supplementary light treatment group in the second round of experiment (4:00-00- 17:00). Compared with the first round of experiment (6:30-17:00), it increased by 2.5 hours. The harvest time of the two rounds of Pakchoi was 35 days after planting. The fresh weight of CK individual plant in the two rounds was similar. The difference in fresh weight per plant in LB and MB treatment compared to CK in the second round of experiments was much greater than the difference in fresh weight per plant compared to CK in the first round of experiments (Table 1, Table 3). The harvest time of the second round of experimental lettuce was 42 days after planting, and the harvest time of the first round of experimental lettuce was 46 days after planting. The number of colonization days when the second round of experimental lettuce CK was harvested was 4 days less than that of the first round, but the fresh weight per plant is 1.57 times that of the first round of experiments (Table 2 and Table 4), and the light energy utilization efficiency is similar. It can be seen that as the temperature gradually warms up and the natural light in the greenhouse gradually increases, the production cycle of lettuce is shortened.

Materials and Methods

The two rounds of testing basically covered the entire winter in Shanghai, and the control group (CK) was able to relatively restore the actual production status of hydroponic green stalk and lettuce in the greenhouse under low temperature and low sunlight in winter. The light supplement experiment group had a significant promotion effect on the most intuitive data index (fresh weight per plant) in the two rounds of experiments. Among them, the yield increase effect of Pakchoi was reflected in the size, color and thickness of the leaves at the same time. But lettuce tends to increase the number of leaves, and the plant shape looks fuller. The test results show that light supplementation can improve the fresh weight and product quality in the planting of the two vegetable categories, thereby increasing the commerciality of vegetable products. Pakchoi supplemented by The red-white, low-blue and red-white, mid-blue LED top-light modules are darker green and shiny in appearance than the leaves without supplemental light, the leaves are larger and thicker, and the growth trend of the whole plant type is more compact and vigorous. However, “mosaic lettuce” belongs to light green leafy vegetables, and there is no obvious color change process in the growth process. The change of leaf color is not obvious for human eyes. The appropriate proportion of blue light can promote leaf development and photosynthetic pigment synthesis, and inhibit internode elongation. Therefore, the vegetables in the light supplement group are more favored by consumers in appearance quality.

During the second round of the test, the total daily cumulative light quantity of the supplementary light group was much higher than the DLI during the same number of colonization days during the first round of the experiment (Figure 1-2), and the supplementary light time of the second round of the supplementary light treatment group (4: 00-17: 00), compared with the first round of experiment (6:30-17: 00), it increased by 2.5 hours. The harvest time of the two rounds of Pakchoi was 35 days after planting. The fresh weight of CK in the two rounds was similar. The difference in fresh weight per plant between LB and MB treatment and CK in the second round of experiments was much larger than the difference in fresh weight per plant with CK in the first round of experiments (Table 1 and Table 3). Therefore, extending the light supplement time can promote the increase in the production of hydroponic Pakchoi cultivated indoor in winter. The harvest time of the second round of experimental lettuce was 42 days after planting, and the harvest time of the first round of experimental lettuce was 46 days after planting. When the second round of experimental lettuce was harvested, the number of colonization days of the CK group was 4 days less than that of the first round. However, the fresh weight of a single plant was 1.57 times that of the first round of experiments (Table 2 and Table 4). The light energy utilization efficiency was similar. It can be seen that as the temperature slowly rises and the natural light in the greenhouse gradually increases (Figure 1-2), the production cycle of lettuce can be shortened accordingly. Therefore, adding supplementary light equipment to the greenhouse in the winter with low temperature and low sunlight can effectively improve the production efficiency of lettuce, and then Increase production. In the first round of experiment, the leaf menu plant supplemented light power consumption was 0.95 kw-h, and in the second round of experiment, the leaf menu plant supplemented light power consumption was 1.15 kw-h. Compared between the two rounds of experiments, the light consumption of the three treatments of Pakchoi, the energy utilization efficiency in the second experiment was lower than that in the first experiment. The light energy utilization efficiency of the lettuce CK and LB supplementary light treatment groups in the second experiment was slightly lower than that in the first experiment. It is inferred that the possible reason is that the low daily average temperature within a week after planting makes the slow seedling period longer, and although the temperature rebounded a little during the experiment, the range was limited, and the overall daily average temperature was still at a low level, which restricted the light energy utilization efficiency during the overall growth cycle for hydroponics of leafy vegetables. (Figure 1).

During the experiment, the nutrient solution pool was not equipped with warming equipment, so that the root environment of hydroponic leafy vegetables was always at a low temperature level, and the daily average temperature was limited, which caused the vegetables to fail to make full use of the daily cumulative light increased by extending the LED supplementary light. Therefore, when supplementing light in the greenhouse in winter, it is necessary to consider appropriate heat preservation and heating measures to ensure the effect of supplementing light to increase production. Therefore, it is necessary to consider appropriate measures of heat preservation and temperature increase to ensure the effect of light supplement and yield increase in winter greenhouse. The use of LED supplementary light will increase the production cost to a certain extent, and agricultural production itself is not a high-yield industry. Therefore, regarding how to optimize the supplementary light strategy and cooperate with other measures in the actual production of hydroponic leafy vegetables in winter greenhouse, and how to use the supplementary light equipment to achieve efficient production and improve the efficiency of light energy utilization and economic benefits, it still needs further production experiments.

Authors: Yiming Ji, Kang Liu, Xianping Zhang, Honglei Mao (Shanghai green cube Agricultural Development Co., Ltd.).

Article source: Agricultural Engineering Technology (Greenhouse Horticulture).

References:

[1] Jianfeng Dai, Philips horticultural LED application practice in greenhouse production [J]. Agricultural engineering technology, 2017, 37 (13): 28-32

[2] Xiaoling Yang, Lanfang Song, Zhengli Jin, et al. Application status and Prospect of light supplement technology for protected fruits and vegetables [J]. Northern horticulture, 2018 (17): 166-170

[3] Xiaoying Liu, Zhigang Xu, Xuelei Jiao, et al. Research and application status and development strategy of plant lighting [J]. Journal of lighting engineering, 013, 24 (4): 1-7

[4] Jing Xie, Hou Cheng Liu, Wei Song Shi, et al. Application of light source and light quality control in greenhouse vegetable production [J]. Chinese vegetable, 2012 (2): 1-7

Post time: May-21-2021