Author: Jing Zhao,Zengchan Zhou,Yunlong Bu,etc. Source Media:Agricultural Engineering Technology (greenhouse horticulture)

The plant factory combines modern industry, biotechnology, nutrient hydroponics and information technology to implement high-precision control of environmental factors in the facility. It is fully enclosed, has low requirements on the surrounding environment, shortens the plant harvest period, saves water and fertilizer, and with the advantages of non-pesticide production and no waste discharge, the unit land use efficiency is 40 to 108 times of that of open field production. Among them, the intelligent artificial light source and its light environment regulation play a decisive role in its production efficiency.

As an important physical environmental factor, light plays a key role in regulating plant growth and material metabolism. “One of the main features of the plant factory is the full artificial light source and the realization of intelligent regulation of the light environment” has become a general consensus in the industry.

Plants’ need for light

Light is the only energy source of plant photosynthesis. Light intensity, light quality (spectrum) and periodic changes of light have a profound impact on the growth and development of crops, among which the light intensity has the greatest impact on plant photosynthesis.

■ Light intensity

The intensity of light can change the morphology of crops, such as flowering, internode length, stem thickness, and leaf size and thickness. The requirements of plants for light intensity can be divided into light-loving, medium-light-loving, and low-light-tolerant plants. Vegetables are mostly light-loving plants, and their light compensation points and light saturation points are relatively high. In artificial light plant factories, the relevant requirements of crops for light intensity are an important basis for selecting artificial light sources. Understanding the light requirements of different plants is important for designing artificial light sources, It is extremely necessary to improve the production performance of the system.

■ Light quality

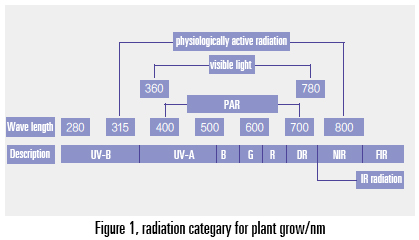

The light quality (spectral) distribution also has an important influence on plant photosynthesis and morphogenesis (Figure 1). Light is part of radiation, and radiation is an electromagnetic wave. Electromagnetic waves have wave characteristics and quantum (particle) characteristics. The quantum of light is called photon in the horticulture field. Radiation with a wavelength range of 300~800nm is called physiologically active radiation of plants; and radiation with a wavelength range of 400~700nm is called photosynthetically active radiation (PAR) of plants.

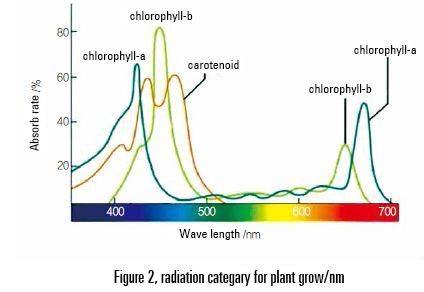

Chlorophyll and carotenes are the two most important pigments in plant photosynthesis. Figure 2 shows the spectral absorption spectrum of each photosynthetic pigment, in which the chlorophyll absorption spectrum is concentrated in the red and blue bands. The lighting system is based on the spectral needs of crops to artificially supplement light, so as to promote the photosynthesis of plants.

■ photoperiod

The relationship between photosynthesis and photomorphogenesis of plants and day length (or photoperiod time) is called photoperiodity of plants. The photoperiodity is closely related to the light hours, which refers to the time the crop is irradiated by light. Different crops require a certain number of hours of light to complete the photoperiod to bloom and bear fruit. According to the different photoperiods, it can be divided into long-day crops, such as cabbage, etc., which require more than 12-14h light hours at a certain stage of its growth; short-day crops, such as onions, soybeans, etc., require less than 12-14h Illumination hours; medium-sun crops, such as cucumbers, tomatoes, peppers, etc., can bloom and bear fruit under longer or shorter sunlight.

Among the three elements of the environment, light intensity is an important basis for selecting artificial light sources. At present, there are many ways to express light intensity, mainly including the following three.

(1)Illumination refers to the surface density of luminous flux (luminous flux per unit area) received on the illuminated plane, in lux (lx).

(2)Photosynthetically active radiation, PAR,Unit:W/m²。

(3)The photosynthetically effective photon flux density PPFD or PPF is the number of photosynthetically effective radiation that reaches or passes through unit time and unit area, unit:μmol/(m²·s)。Mainly refers to the light intensity of 400~700nm directly related to photosynthesis. It is also the most commonly used light intensity indicator in the field of plant production.

Light source analysis of typical supplementary light system

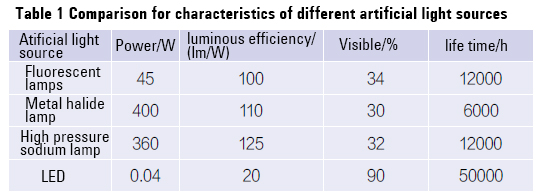

Artificial light supplement is to increase the light intensity in the target area or extend the light time by installing a supplement light system to fulfill the light demand of plants. Generally speaking, the supplementary light system includes supplementary light equipment, circuits and its control system. Supplementary light sources mainly include several common types such as incandescent lamps, fluorescent lamps, metal halide lamps, high-pressure sodium lamps and LEDs. Due to the low electrical and optical efficiency of incandescent lamps, low photosynthetic energy efficiency and other shortcomings, it has been eliminated by the market, so this article does not make a detailed analysis.

■ Fluorescent lamp

Fluorescent lamps belong to the type of low-pressure gas discharge lamps. The glass tube is filled with mercury vapor or inert gas, and the inner wall of the tube is coated with fluorescent powder. The light color varies with the fluorescent material coated in the tube. Fluorescent lamps have good spectral performance, high luminous efficiency, low power, longer life (12000h) compared with incandescent lamps, and relatively low cost. Because the fluorescent lamp itself emits less heat, it can be close to the plants for lighting and is suitable for three-dimensional cultivation. However, the spectral layout of the fluorescent lamp is unreasonable. The most common method in the world is to add reflectors to maximize the effective light source components of the crops in the cultivation area. Japanese adv-agri company has also developed a new type of supplementary light source HEFL. HEFL actually belongs to the category of fluorescent lamps. It is the general term for cold cathode fluorescent lamps (CCFL) and external electrode fluorescent lamps (EEFL), and is a mixed electrode fluorescent lamp. The HEFL tube is extremely thin, with a diameter of only about 4mm, and the length can be adjusted from 450mm to 1200mm according to the needs of cultivation. It is an improved version of the conventional fluorescent lamp.

■ Metal halide lamp

The metal halide lamp is a high-intensity discharge lamp that can excite different elements to produce different wavelengths by adding various metal halides (tin bromide, sodium iodide, etc.) in the discharge tube on the basis of a high-pressure mercury lamp. Halogen lamps have high luminous efficiency, high power, good light color, long life, and large spectrum. However, because the luminous efficiency is lower than that of high-pressure sodium lamps, and the lifetime is shorter than that of high-pressure sodium lamps, it is currently only used in a few plant factories.

■ High pressure sodium lamp

High-pressure sodium lamps belong to the type of high-pressure gas discharge lamps. The high-pressure sodium lamp is a high-efficiency lamp in which high-pressure sodium vapor is filled in the discharge tube, and a small amount of xenon (Xe) and mercury metal halide are added. Because high pressure sodium lamps have high electro-optical conversion efficiency with lower manufacturing costs, high pressure sodium lamps are currently the most widely used in the application of supplementary light in agricultural facilities. However, due to the shortcomings of low photosynthetic efficiency in their spectrum, they have the shortcomings of low energy efficiency. On the other hand, the spectral components emitted by high-pressure sodium lamps are mainly concentrated in the yellow-orange light band, which lacks the red and blue spectra necessary for plant growth.

■ Light emitting diode

As a new generation of light sources, light-emitting diodes (LEDs) have many advantages such as higher electro-optical conversion efficiency, adjustable spectrum, and high photosynthetic efficiency. LED can emit monochromatic light needed for plant growth. Compared with ordinary fluorescent lamps and other supplementary light sources, LED has the advantages of energy saving, environmental protection, long life, monochromatic light, cold light source and so on. With the further improvement of the electro-optical efficiency of LEDs and the reduction of costs caused by the scale effect, LED grow lighting systems will become the mainstream equipment for supplementing light in agricultural facilities. As a result, LED grow lights have been applied over 99.9% plant factories.

Through comparison, the characteristics of different supplementary light sources can be clearly understood, as shown in Table 1.

Mobile lighting device

The intensity of light is closely related to the growth of crops. Three-dimensional cultivation is often used in plant factories. However, due to the limitation of the structure of the cultivation racks, the uneven distribution of light and temperature between the racks will affect the yield of the crops and the harvesting period will not be synchronized. A company in Beijing has successfully developed a manual lifting light supplement device(HPS lighting fixture and LED grow lighting fixture) in 2010. The principle is to rotate the drive shaft and the winder fixed on it by shaking the handle to rotate the small film reel to achieve the purpose of retracting and unwinding the wire rope. The wire rope of the grow light is connected with the winding wheel of the elevator through multiple sets of reversing wheels, so as to achieve the effect of adjusting the height of the grow light. In 2017, the above-mentioned company designed and developed a new mobile light supplement device, which can automatically adjust the light supplement height in real time according to crop growth needs. The adjustment device is now installed on the 3-layer light source lifting type three-dimensional cultivation rack. The top layer of the device is the level with the best light condition, so it is equipped with high-pressure sodium lamps; the middle layer and the bottom layer are equipped with LED grow lights and a lifting adjustment system. It can automatically adjust the height of the grow light to provide a suitable lighting environment for the crops.

Compared with the mobile light supplement device tailored for three-dimensional cultivation, the Netherlands has developed a horizontally movable LED grow light supplement light device. In order to avoid the influence of the shadow of the grow light on the growth of plants in the sun, the grow light system can be pushed to both sides of the bracket through the telescopic slide in the horizontal direction, so that the sun is fully irradiated on the plants; on cloudy and rainy days without sunlight, Push the grow light system to the middle of the bracket to make the light of the grow light system evenly fill the plants; move the grow light system horizontally through the slide on the bracket, avoid frequent disassembly and removal of the grow light system, and reduce the labor intensity of employees, thus effectively improving work efficiency.

Design ideas of typical grow light system

It is not difficult to see from the design of the mobile lighting supplementary device that the design of the supplementary lighting system of the plant factory usually takes the light intensity, light quality and photoperiod parameters of different crop growth periods as the core content of the design, relying on the intelligent control system to implement, achieving the ultimate goal of energy saving and high yield.

At present, the design and construction of supplementary light for leafy vegetables has gradually matured. For example, leafy vegetables can be divided into four stages: seedling stage, mid-growth, late-growth, and end stage; fruit-vegetables can be divided into seedling stage, vegetative growth stage, flowering stage, and harvesting stage. From the attributes of supplemental light intensity, the light intensity in the seedling stage should be slightly lower, at 60~200 μmol/(m²·s), and then gradually increase. Leafy vegetables can reach up to 100~200 μmol/(m²·s), and fruit vegetables can reach 300~500 μmol/(m²·s) to ensure the light intensity requirements of plant photosynthesis in each growth period and fulfill the needs of high yield; In terms of light quality, the ratio of red to blue is very important. In order to increase the quality of seedlings and prevent excessive growth in the seedling stage, the ratio of red to blue is generally set at a low level [(1~2):1], and then gradually reduced to meet the needs of plant light morphology. The ratio of red to blue to leafy vegetables can be set to (3~6):1. For the photoperiod, similar to the light intensity, it should show a trend of increasing with the extension of the growth period, so that leafy vegetables have more photosynthetic time for photosynthesis. The light supplement design of fruits and vegetables will be more complicated. In addition to the above-mentioned basic laws, we should focus on the setting of the photoperiod during the flowering period, and the flowering and fruiting of vegetables must be promoted, so as not to backfire.

It is worth mentioning that the light formula should include the end treatment for light environment settings. For example, continuous light supplementation can greatly improve the yield and quality of hydroponic leafy vegetable seedlings, or use UV treatment to significantly improve sprouts and leafy vegetables (especially purple Leaves and red leaf lettuce) nutritional quality.

In addition to optimizing light supplementation for selected crops, the light source control system of some artificial light plant factories has also developed rapidly in recent years. This control system is generally based on the B/S structure. Remote control and automatic control of environmental factors such as temperature, humidity, light, and CO2 concentration during the growth of crops are realized through WIFI, and at the same time, a production method that is not restricted by external conditions is realized. This kind of intelligent supplementary light system uses LED grow light fixture as supplementary light source, combined with remote intelligent control system, can meet the needs of plant wavelength illumination, is particularly suitable for light-controlled plant cultivation environment, and can well meet market demand.

Concluding remarks

Plant factories are considered to be an important way to solve world resource, population and environmental problems in the 21st century, and an important way to achieve food self-sufficiency in future high-tech projects. As a new type of agricultural production method, plant factories are still in the learning and growth stage, and more attention and research are needed. This article describes the characteristics and advantages of common supplementary lighting methods in plant factories, and introduces the design ideas of typical crop supplementary lighting systems. It is not difficult to find through comparison, in order to cope with the low light caused by severe weather such as continuous cloudy and haze and to ensure high and stable production of facility crops, LED Grow light source equipment is most in line with current development trends.

The future development direction of plant factories should focus on new high-precision, low-cost sensors, remotely controllable, adjustable spectrum lighting device systems and expert control systems. At the same time, the future plant factories will continue to develop towards low-cost, intelligent, and self-adaptive. The use and popularization of LED grow light sources provide guarantee for high-precision environmental control of plant factories. LED light environment regulation is a complex process involving comprehensive regulation of light quality, light intensity, and photoperiod. Relevant experts and scholars need to conduct in-depth research, promoting LED supplementary lighting in artificial light plant factories.

Post time: Mar-05-2021