Abstract

At present, the plant factory has successfully realized the breeding of vegetable seedlings such as cucumbers, tomatoes, peppers, eggplants, and melons, providing farmers with high-quality seedlings in batches, and the production performance after planting is better. Plant factories have become an important means of seedling supply for the vegetable industry, and play an increasingly important role in promoting the supply-side structural reform of the vegetable industry, ensuring urban vegetable supply and green vegetable production.

Plant factory seedling breeding system design and key technical equipment

As the most efficient agricultural production system at present, the plant factory seedling breeding system integrates comprehensive technical means including artificial lighting, nutrient solution supply, three-dimensional environmental control, automated auxiliary operations, intelligent production management, etc., and integrates biotechnology, information technology and artificial intelligence. Intelligent and other high-tech achievements promote the continuous development of the industry.

LED artificial light source system

The construction of artificial light environment is one of the core technologies of the seedling breeding system in plant factories, and it is also the main source of energy consumption for seedling production. The light environment of plant factories has strong flexibility, and the light environment can be regulated from multiple dimensions such as light quality, light intensity and photoperiod, and at the same time, different light factors can be optimized and combined in time sequence to form a light formula for seedling cultivation, ensuring suitable light environment for artificial cultivation of seedlings. Therefore, based on the light demand characteristics and production goals of different seedling growth, by optimizing the light formula parameters and light supply strategy, a special energy-saving LED light source has been developed, which can greatly improve the light energy conversion efficiency of seedlings, promote the accumulation of seedling biomass, and improve the quality of seedling production, while reducing energy consumption and production costs. In addition, light environment regulation is also an important technical means in the process of domestication of seedlings and healing of grafted seedlings.

Detachable multi-layer vertical seedling system

The seedling breeding in the plant factory is carried out by using a multi-layer three-dimensional shelf. Through the modular system design, the rapid assembly of the seedling raising system can be realized. The spacing between the shelves can be flexibly adjusted to meet the space requirements for the breeding of different varieties of seedlings and greatly improve the space utilization rate. In addition, the separate design of the seedbed system, lighting system, and water and fertilizer irrigation system enables the seedbed to have both a transport function, which is convenient for moving to different workshops such as sowing, germination and domestication, and reduces the labor consumption of seedling tray handling.

Detachable multi-layer vertical seedling system

Water and fertilizer irrigation mainly adopts tidal type, spray type and other methods, through precise control of the time and frequency of nutrient solution supply, to achieve uniform supply and efficient use of water and mineral nutrients. Combined with the special nutrient solution formula for seedlings, it can meet the growth and development needs of seedlings and ensure the rapid and healthy growth of seedlings. In addition, through the online nutrient ion detection system and nutrient solution sterilization system, nutrients can be replenished in time, while avoiding the accumulation of microorganisms and secondary metabolites that affect the normal growth of seedlings.

Environmental Control System

Precise and efficient environmental control is one of the main features of a plant factory seedling propagation system. The external maintenance structure of a plant factory is generally assembled from materials that are opaque and highly insulating. On this basis, the regulation of light, temperature, humidity, wind speed, and CO2 is almost unaffected by the external environment. Through the construction of the CFD model to optimize the layout of the air duct, combined with the micro-environment control method, the uniform distribution of environmental factors such as temperature, humidity, wind speed, and CO2 in the high-density culture space can be achieved. The intelligent environment regulation is realized by distributed sensors and contact control, and the real-time regulation of the entire cultivation environment is carried out through the connection between the monitoring unit and the control system. In addition, the use of water-cooled light sources and water circulation, combined with the introduction of outdoor cold sources, can achieve energy-saving cooling and reduce air-conditioning energy consumption.

Automatic auxiliary operation equipment

The plant factory seedling breeding operation process is strict, the operation density is high, the space is compact, and automatic auxiliary equipment is indispensable. The use of automated auxiliary equipment is not only conducive to reducing labor consumption, but also helps to improve the efficiency of cultivation space. The automation equipment that has been developed so far includes plug soil covering machine, seeder, grafting machine, AGV logistics conveying trolley, etc. Under the control of the supporting intelligent management platform, the unmanned operation of the whole process of seedling breeding can basically be realized. In addition, machine vision technology also plays an increasingly important role in the process of seedling breeding. It not only helps to monitor the growth status of seedlings, assists in the management of commercial seedlings, but also performs automatic screening of weak seedlings and dead seedlings. The robot hand removes and fills the seedlings.

Advantages of plant factory seedling breeding

High level of environmental control enables annual production

Due to the particularity of seedling breeding, the control of its cultivation environment is very important. Under the plant factory conditions, environmental factors such as light, temperature, water, air, fertilizer and CO2 are highly controlled, which can provide the best growth environment for seedling breeding, regardless of seasons and regions. In addition, in the breeding process of grafted seedlings and cutting seedlings, the process of grafting wound healing and root differentiation requires higher environmental control, and plant factories are also excellent carriers. The flexibility of the environmental conditions of the plant factory itself is strong, so it is of great significance for the production of vegetable seedlings in non-breeding seasons or in extreme environments, and can provide seedling support to ensure the perennial supply of vegetables. In addition, the seedling breeding of plant factories is not limited by space, and can be carried out on the spot in the suburbs of cities and community public spaces. The specifications are flexible and changeable, enabling mass production and close supply of high-quality seedlings, providing important support for the development of urban horticulture.

Shorten the breeding cycle and improve the quality of seedlings

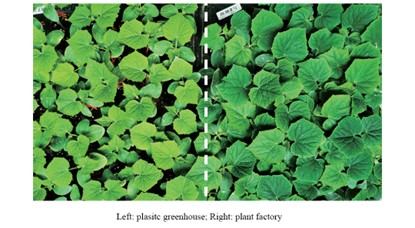

Under plant factory conditions, thanks to the precise control of various growth environmental factors, the seedling breeding cycle is shortened by 30% to 50% compared to traditional methods. The shortening of the breeding cycle can increase the production batch of seedlings, increase the producer’s income, and reduce the operating risks caused by market fluctuations. For growers, it is conducive to early transplanting and planting, early market launch, and improved market competitiveness. On the other hand, the seedlings bred in the plant factory are neat and stout, the morphological and quality indicators are significantly improved, and the production performance after colonization is better. Studies have shown that tomato, pepper and cucumber seedlings bred under plant factory conditions not only improve leaf area, plant height, stem diameter, root vigor and other indicators, but also improve adaptability, disease resistance, flower bud differentiation after colonization. And the production and other aspects have obvious advantages. The number of female flowers per plant increased by 33.8% and the number of fruit per plant increased by 37.3% after planting of cucumber seedlings bred in plant factories. With the continuous deepening of theoretical research on the biology of seedling developmental environment, plant factories will be more precise and controllable in shaping seedling morphology and improving physiological activity.

Comparison of the state of grafted seedlings in greenhouses and plant factories

Efficient use of resources to reduce seedling costs

The plant factory adopts standardized, informatized and industrialized planting methods, so that every link of seedling production is strictly controlled, and the efficiency of resource utilization is significantly improved. Seeds are the main cost consumption in seedling breeding. Due to irregular operation and poor environmental controllability of traditional seedlings, there are problems such as non-germination or weak growth of seeds, resulting in huge waste in the process from seeds to commercial seedlings. In the plant factory environment, through seed pretreatment, fine sowing and precise control of the cultivation environment, the utilization efficiency of seeds is greatly improved, and the dosage can be reduced by more than 30%. Water, fertilizer and other resources are also the main cost consumption of traditional seedling raising, and the phenomenon of resource waste is serious. Under the conditions of plant factories, through the application of precision irrigation technology, the efficiency of water and fertilizer utilization can be increased by more than 70%. In addition, due to the compactness of the structure of the plant factory itself and the uniformity of environmental control, the energy and CO2 utilization efficiency in the process of seedling propagation is also significantly improved.

Compared with traditional open field seedling raising and greenhouse seedling raising, the biggest feature of seedling breeding in plant factories is that it can be carried out in a multi-layered three-dimensional manner. In the plant factory, seedling breeding can be extended from the plane to the vertical space, which greatly improves the seedling breeding efficiency per unit of land and significantly improves the space utilization efficiency. For example, the standard module for seedling breeding developed by a biological company, under the condition of covering an area of 4.68 ㎡, can breed more than 10,000 seedlings in a single batch, which can be used for 3.3 Mu (2201.1 ㎡) vegetable production needs. Under the condition of high-density multi-layer three-dimensional breeding, supporting automatic auxiliary equipment and intelligent logistics transportation system can greatly improve the efficiency of labor utilization and save labor by more than 50%.

High resistance seedling breeding to help green production

The clean production environment of the plant factory can greatly reduce the occurrence of pests and diseases in the breeding space. At the same time, through the optimized configuration of the culture environment, the produced seedlings will have higher resistance, which can greatly reduce the pesticide spraying during seedling propagation and planting. In addition, for the breeding of special seedlings such as grafted seedlings and cutting seedlings, green control measures such as light, temperature, water and fertilizer in the plant factory can be used to replace the large-scale use of hormones in traditional operations to ensure food safety, reduce environmental pollution, and achieve green seedlings Sustainable production.

Production cost analysis

The ways for plant factories to increase the economic benefits of seedlings mainly include two parts. On the one hand, by optimizing structural design, standardized operation and the use of intelligent facilities and equipment, it can reduce the consumption of seeds, electricity and labor in the process of seedling breeding, and improve water, fertilizer, heat, and energy consumption. The utilization efficiency of gas and CO2 reduces the cost of seedling breeding; on the other hand, through precise control of the environment and optimization of the process flow, the breeding time of seedlings is shortened, and the annual breeding batch and seedling yield per unit space are increased, which is more competitive in the market.

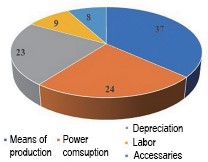

With the development of plant factory technology and the continuous deepening of environmental biology research on seedling cultivation, the cost of seedling breeding in plant factories is basically the same as that of traditional greenhouse cultivation, and the quality and market value of seedlings are higher. Taking cucumber seedlings as an example, the production materials account for a large proportion, accounting for about 37% of the total cost, including seeds, nutrient solution, plug trays, substrates, etc. Electric energy consumption accounts for about 24% of the total cost, including plant lighting, air conditioning and nutrient solution pump energy consumption, etc., which is the main direction of future optimization. In addition, the low proportion of labor is a feature of plant factory production. With the continuous increase in the degree of automation, the cost of labor consumption will be further reduced. In the future, the economic benefits of seedling breeding in plant factories can be further improved through the development of high value-added crops and the development of industrialized cultivation technology for seedlings of precious forest trees.

Cucumber seedling cost composition /%

Industrialization Status

In recent years, scientific research institutions represented by the Urban Agriculture Research Institute of the Chinese Academy of Agricultural Sciences, and high-tech enterprises have realized the industry of seedling breeding in plant factories. It can provide seedlings with an efficient industrial production line from seed to emergence. Among them, a plant factory in Shanxi built and put into operation in 2019 covers an area of 3,500 ㎡ and can breed 800,000 pepper seedlings or 550,000 tomato seedlings within a 30-day cycle. Another seedling breeding plant factory built covers an area of 2300 ㎡ and can produce 8-10 million seedlings per year. The mobile healing plant for grafted seedlings independently developed by the Institute of Urban Agriculture, Chinese Academy of Agricultural Sciences can provide an assembly-line healing and domestication platform for the cultivation of grafted seedlings. A single working space can handle more than 10,000 grafted seedlings at a time. In the future, the diversity of seedling breeding varieties in plant factories is expected to be further expanded, and the level of automation and intelligence will continue to improve.

The mobile healing plant for grafted seedlings developed by the Institute of Urban Agriculture, Chinese Academy of Agricultural Sciences

Outlook

As a new carrier of factory seedling raising, plant factories have huge advantages and commercialization potential compared with traditional seedling raising methods in terms of precise environmental control, efficient utilization of resources and standardized operations. By reducing the consumption of resources such as seeds, water, fertilizer, energy and manpower in seedling breeding, and improving the yield and quality of seedlings per unit area, the cost of seedling breeding in plant factories will be further reduced, and the products will be more competitive in the market. There is a huge demand for seedlings in China. In addition to the production of traditional crops such as vegetables, high value-added seedlings such as flowers, Chinese herbal medicines and rare trees are expected to be bred in plant factories, and the economic benefits will be further improved. At the same time, the industrialized seedling breeding platform needs to consider the compatibility and flexibility of different seedling breeding to meet the needs of the seedling breeding market in different seasons.

The biological theory of seedling breeding environment is the core of precise control of plant factory environment. In-depth research on the regulation of seedling plant shape and photosynthesis and other physiological activities by environmental factors such as light, temperature, humidity and CO2 will help to establish a seedling-environment interaction model, which can reduce the energy consumption of seedling production and improve the quality and production of seedlings. Quality provides a theoretical basis. On this basis, control technology and equipment with light as the core and coupled with other environmental factors, and customize the production of seedlings with special plant types, high uniformity and high quality to meet the requirements of high-density cultivation and mechanized operation in plant factories can be developed. Ultimately, it provides a technical basis for the construction of a digital seedling production system and realizes standardized, unmanned and digital seedling breeding in plant factories.

Author: Xu Yaliang, Liu Xinying, etc.

Citation information:

Xu Yaliang, Liu Xinying, Yang Qichang.Key technical equipment and industrialization of seedling breeding in plant factories [J]. Agricultural Engineering Technology, 2021,42(4):12-15.

Post time: May-26-2022