[Abstract]Based on a large number of experimental data, this article discusses several important issues in the selection of light quality in plant factories, including the selection of light sources, the effects of red, blue and yellow light, and the selection of spectral ranges, in order to provide insights into light quality in plant factories. The determination of matching strategy provides some practical solutions that can be used for reference.

Selection of light source

Plant factories generally use LED lights. This is because LED lights have the characteristics of high luminous efficiency, low energy consumption, less heat generation, long life and adjustable light intensity and spectrum, which can not only meet the requirements of plant growth and effective material accumulation, but also save energy, reduce heat generation and electricity costs. LED grow lights can be further divided into single-chip wide-spectrum LED lights for general purpose, single-chip plant-specific wide-spectrum LED lights, and multi-chip combined adjustable-spectrum LED lights. The price of the latter two kinds of plant-specific LED lights is generally more than 5 times that of ordinary LED lights, so different light sources should be selected according to different purposes. For large plant factories, the types of plants they grow change with market demand. In order to reduce construction costs and not significantly affect production efficiency, the author recommends using broad-spectrum LED chips for general lighting as the lighting source. For small plant factories, if the types of plants are relatively fixed, in order to obtain high production efficiency and quality without significantly increasing the construction cost, wide-spectrum LED chips for plant-specific or general lighting can be used as the lighting source. If it is to study the effect of light on plant growth and accumulation of effective substances, so as to provide the best light formula for large-scale production in the future, a multi-chip combination of adjustable spectrum LED lights can be used to change factors such as light intensity, spectrum and light time to obtain the best light formula for each plant therefor providing the basis for large-scale production.

The red and blue light

As far as the specific experimental results are concerned, when the content of red light (R) is higher than that of blue light (B) (lettuce R:B = 6:2 and 7:3; spinach R:B = 4:1; gourd seedlings R:B = 7:3; cucumber seedlings R:B = 7:3), the experiment showed that the biomass content (including the plant height of the aerial part, the maximum Leaf area, fresh weight and dry weight, etc.) were higher, but the stem diameter and strong seedling index of the plants were larger when the blue light content was higher than that of red light. For biochemical indicators, the content of red light higher than blue light is generally beneficial to the increase of soluble sugar content in plants. However, for the accumulation of VC, soluble protein, chlorophyll and carotenoids in plants, it is more advantageous to use LED lighting with higher blue light content than red light, and the content of malondialdehyde is also relatively low under this lighting condition.

Since the plant factory is mainly used for cultivating leafy vegetables or for industrial seedling raising, it can be concluded from the above results that under the premise of increasing the yield and taking into account the quality, it is suitable to use LED chips with higher red light content than blue light as the light source. A better ratio is R:B = 7:3. What’s more, such a ratio of red and blue light is basically applicable to all kinds of leafy vegetables or seedlings, and there are no specific requirements for different plants.

Red and blue wavelength selection

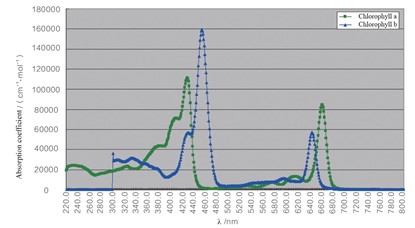

During photosynthesis, light energy is mainly absorbed through chlorophyll a and chlorophyll b. The figure below shows the absorption spectra of chlorophyll a and chlorophyll b, where the green spectral line is the absorption spectrum of chlorophyll a, and the blue spectral line is the absorption spectrum of chlorophyll b. It can be seen from the figure that both chlorophyll a and chlorophyll b have two absorption peaks, one in the blue light region and the other in the red light region. But the 2 absorption peaks of chlorophyll a and chlorophyll b are slightly different. To be precise, the two peak wavelengths of chlorophyll a are 430 nm and 662 nm, respectively, and the two peak wavelengths of chlorophyll b are 453 nm and 642 nm, respectively. These four wavelength values will not change with different plants, so the selection of red and blue wavelengths in the light source will not change with different plant species.

Absorption spectra of chlorophyll a and chlorophyll b

Absorption spectra of chlorophyll a and chlorophyll b

An ordinary LED lighting with a broad spectrum can be used as the light source of the plant factory, as long as the red and blue light can cover the two peak wavelengths of chlorophyll a and chlorophyll b, that is, the wavelength range of red light is generally 620~680 nm, while the blue light The wavelength range is from 400 to 480 nm. However, the wavelength range of red and blue light should not be too wide because it not only wastes light energy, but may also have other impacts.

If an LED light composed of red, yellow and blue chips is used as the light source of the plant factory, the peak wavelength of red light should be set to the peak wavelength of chlorophyll a, that is, at 660 nm, the peak wavelength of blue light should be set to the peak wavelength of chlorophyll b, i.e. at 450 nm.

The role of yellow and green light

It is more appropriate when the ratio of red, green and blue light is R:G:B=6:1:3. As for the determination of the green light peak wavelength, since it mainly plays a regulatory role in the process of plant growth, it only needs to be between 530 and 550 nm.

Summary

This article discusses the selection strategy of light quality in plant factories from both theoretical and practical aspects, including the selection of the wavelength range of red and blue light in the LED light source and the role and ratio of yellow and green light. In the process of plant growth, the reasonable matching between the three factors of light intensity, light quality and light time, and their relationship with nutrients, temperature and humidity, and CO2 concentration should also be comprehensively considered. For actual production, whether you plan to use a wide spectrum or a multi-chip combination tunable spectrum LED light, the ratio of wavelengths is the primary consideration, because in addition to light quality, other factors can be adjusted in real time during operation . Therefore, the most important consideration in the design stage of plant factories should be the selection of light quality.

Author: Yong Xu

Article source: Wechat account of Agricultural Engineering Technology (greenhouse horticulture)

Reference: Yong Xu, Light quality selection strategy in plant factories [J]. Agricultural Engineering Technology, 2022, 42(4): 22-25.

Post time: Apr-25-2022