Greenhouse horticultural agricultural engineering technology 2022-12-02 17:30 published in Beijing

Developing solar greenhouses in non-cultivated areas such as desert, Gobi and sandy land has effectively solved the contradiction between food and vegetables competing for land. It is one of the decisive environmental factors for the growth and development of temperature crops, which often determines the success or failure of greenhouse crop production. Therefore, to develop solar greenhouses in non-cultivated areas, we must first solve the environmental temperature problem of greenhouses. In this article, the temperature control methods used in non-cultivated land greenhouses in recent years are summarized, and the existing problems and development direction of temperature and environmental protection in non-cultivated land solar greenhouses are analyzed and summarized.

China has a large population and less available land resources. More than 85% of the land resources are non-cultivated land resources, which are mainly concentrated in the northwest of China. Document No.1 of the Central Committee in 2022 pointed out that the development of facility agriculture should be accelerated, and on the basis of protecting the ecological environment, the exploitable vacant land and wasteland should be explored to develop facility agriculture. Northwest China is rich in desert, Gobi, wasteland and other non-cultivated land resources and natural light and heat resources, which are suitable for the development of facility agriculture. Therefore, the development and utilization of non-cultivated land resources to develop non-cultivated land greenhouses is of great strategic significance for ensuring national food security and alleviating land use conflicts.

At present, non-cultivated solar greenhouse is the main form of high-efficiency agricultural development in non-cultivated land. In the northwest of China, the temperature difference between day and night is large, and the temperature at night in winter is low, which often leads to the phenomenon that the indoor minimum temperature is lower than the temperature required for the normal growth and development of crops. Temperature is one of the indispensable environmental factors for the growth and development of crops. Too low temperature will slow down the physiological and biochemical reaction of crops and slow their growth and development. When the temperature is lower than the limit that crops can bear, it will even lead to freezing injury. Therefore, it is particularly important to ensure the temperature required for the normal growth and development of crops. To maintain the proper temperature of solar greenhouse, it is not a single measure that can be solved. It needs to be guaranteed from the aspects of greenhouse design, construction, material selection, regulation and daily management. Therefore, this article will summarize the research status and progress of temperature control of non-cultivated greenhouses in China in recent years from the aspects of greenhouse design and construction, heat preservation and warming measures and environmental management, so as to provide a systematic reference for the rational design and management of non-cultivated greenhouses.

Greenhouse structure and materials

The thermal environment of greenhouse mainly depends on the transmission, interception and storage capacity of greenhouse to solar radiation, which is related to the reasonable design of greenhouse orientation, shape and material of light-transmitting surface, structure and material of wall and back roof, foundation insulation, greenhouse size, night insulation mode and material of front roof, etc., and also relates to whether the construction and construction process of greenhouse can ensure the effective realization of design requirements.

Light transmission capacity of front roof

The main energy in the greenhouse comes from the sun. Increasing the light transmission capacity of the front roof is beneficial for the greenhouse to obtain more heat, and it is also an important foundation to ensure the temperature environment of the greenhouse in winter. At present, there are three main methods to increase the light transmission capacity and light receiving time of the front roof of greenhouse.

01 design reasonable greenhouse orientation and azimuth

The orientation of greenhouse affects the lighting performance of greenhouse and the heat storage capacity of greenhouse. Therefore, in order to get more heat storage in greenhouse, the orientation of non-cultivated greenhouses in northwest China is facing south. For the specific azimuth of greenhouse, when choosing south to east, it is beneficial to “grab the sun”, and the indoor temperature rises quickly in the morning; When south to west is selected, it is beneficial for greenhouse to make use of afternoon light. The south direction is a compromise between the above two situations. According to the knowledge of geophysics, the earth rotates 360°in a day, and the azimuth of the sun moves about 1° every 4 minutes. Therefore, every time the azimuth of the greenhouse differs by 1°, the time of direct sunlight will differ by about 4 minutes, that is, the azimuth of the greenhouse affects the time when the greenhouse sees light in the morning and evening.

When the morning and afternoon light hours are equal, and the east or west are at the same angle, the greenhouse will get the same light hours. However, for the area north of 37° north latitude, the temperature is low in the morning, and the time of quilt uncovering is late, while the temperature is relatively high in the afternoon and evening, so it is appropriate to delay the time of closing the thermal insulation quilt. Therefore, these areas should choose south to west and make full use of the afternoon light. For the areas with 30°~35° north latitude, because of the better lighting conditions in the morning, the time of heat preservation and cover uncovering can also be advanced. Therefore, these areas should choose the south-by-east direction to strive for more morning solar radiation for the greenhouse. However, in the area of 35°~37°north latitude, there is little difference in solar radiation in the morning and afternoon, so it is better to choose due south direction. Whether it’s south-east or south-west, the deviation angle is generally 5° ~8°, and the maximum shall not exceed 10°. Northwest China lies in the range of 37°~50°north latitude, so the azimuth angle of greenhouse is generally from south to west. In view of this, the sunlight greenhouse designed by Zhang Jingshe etc. in Taiyuan area has chosen the orientation of 5° to the west of the south, the sunlight greenhouse built by Chang Meimei etc. in Gobi area of Hexi Corridor has adopted the orientation of 5° to 10° to the west of the south, and the sunlight greenhouse built by Ma Zhigui etc. in northern Xinjiang has adopted the orientation of 8° to the west of the south.

02 Design reasonable front roof shape and inclination angle

The shape and inclination of the front roof determine the incident angle of the sun rays. The smaller the incident angle, the greater the transmittance. Sun Juren believes that the shape of the front roof is mainly determined by the ratio of the length of the main lighting surface and the rear slope. Long front slope and short rear slope are beneficial to the lighting and heat preservation of the front roof. Chen Wei-Qian and others think that the main lighting roof of solar greenhouse used in Gobi area adopts a circular arc with a radius of 4.5m, which can effectively resist the cold. Zhang Jingshe, etc. think that it is more appropriate to use semi-circular arch on the front roof of greenhouse in alpine and high latitude areas. As for the inclination angle of the front roof, according to the light transmission characteristics of plastic film, when the incident angle is 0 ~ 40°, the reflectivity of the front roof to the sunlight is small, and when it exceeds 40°, the reflectivity increases significantly. Therefore, 40° is taken as the maximum incident angle to calculate the inclination angle of the front roof, so that even in the winter solstice, the solar radiation can enter the greenhouse to the maximum extent. Therefore, when designing a solar greenhouse suitable for non-cultivated areas in Wuhai, Inner Mongolia, He Bin and others calculated the inclination angle of the front roof with an incident angle of 40°, and thought that as long as it was greater than 30°, it could meet the requirements of greenhouse lighting and heat preservation. Zhang Caihong and others think that when building greenhouses in Xinjiang’s non-cultivated areas, the inclination angle of the front roof of greenhouses in southern Xinjiang is 31°, while that in northern Xinjiang is 32°~33.5°.

03 Choose suitable transparent covering materials.

In addition to the influence of outdoor solar radiation conditions, the material and light transmission characteristics of greenhouse film are also important factors affecting the light and heat environment of greenhouse. At present, the light transmittance of plastic films such as PE, PVC, EVA and PO is different due to different materials and film thicknesses. Generally speaking, the light transmittance of films that have been used for 1-3 years can be guaranteed to be above 88% on the whole, which should be selected according to the demand of crops for light and temperature. In addition, in addition to the light transmission in greenhouse, the distribution of light environment in greenhouse is also a factor that people pay more and more attention to. Therefore, in recent years, the light transmission covering material with enhanced scattering light has been highly recognized by the industry, especially in the areas with strong solar radiation in northwest China. The application of enhanced scattering light film has reduced the shading effect on the top and bottom of crop canopy, increased the light in the middle and lower parts of crop canopy, improved the photosynthetic characteristics of the whole crop, and showed a good effect of promoting growth and increasing production.

Reasonable design of greenhouse size

The length of greenhouse is too long or too short, which will affect the indoor temperature control. When the length of greenhouse is too short, before sunrise and sunset, the area shaded by the east and west gables is large, which is not conducive to the greenhouse’s warming, and because of its small volume, it will affect the indoor soil and wall’s absorption and release of heat. When the length is too large, it is difficult to control the indoor temperature, and it will affect the firmness of the greenhouse structure and the configuration of the heat preservation quilt rolling mechanism. The height and span of the greenhouse directly affect the daylighting of the front roof, the size of the greenhouse space and the insulation ratio. When the span and length of the greenhouse are fixed, increasing the height of the greenhouse can increase the lighting angle of the front roof from the perspective of light environment, which is conducive to light transmission; From the point of view of thermal environment, the height of the wall increases, and the heat storage area of the back wall increases, which is beneficial to the heat storage and heat release of the back wall. Moreover, the space is large, the heat capacity rate is also large, and the thermal environment of the greenhouse is more stable. Of course, increasing the height of greenhouse will increase the cost of greenhouse, which needs comprehensive consideration. Therefore, when designing a greenhouse, we should choose a reasonable length, span and height according to local conditions. For example, Zhang Caihong and others think that in northern Xinjiang, the length of greenhouse is 50~80m, the span is 7m and the height of greenhouse is 3.9m, while in southern Xinjiang, the length of greenhouse is 50~80m, the span is 8m and the height of greenhouse is 3.6~4.0m; It is also considered that the span of greenhouse should not be less than 7m, and when the span is 8m, the heat preservation effect is the best. In addition, Chen Weiqian and others think that the length, span and height of the solar greenhouse should be 80m, 8~10m and 3.8~4.2m respectively when it is built in the Gobi area of Jiuquan, Gansu.

Improve the heat storage and insulation capacity of the wall

During the daytime, the wall accumulates heat by absorbing the solar radiation and the heat of some indoor air. At night, when the indoor temperature is lower than the wall temperature, the wall will passively release heat to heat the greenhouse. As the main heat storage body of greenhouse, the wall can significantly improve the indoor night temperature environment by improving its heat storage capacity. At the same time, the thermal insulation function of the wall is the basis for the stability of the greenhouse thermal environment. At present, there are several methods to improve the heat storage and insulation capacity of walls.

01 design reasonable wall structure

The function of the wall mainly includes heat storage and heat preservation, and at the same time, most of the greenhouse walls also serve as load-bearing members to support the roof truss. From the point of view of obtaining a good thermal environment, a reasonable wall structure should have enough heat storage capacity on the inner side and enough heat preservation capacity on the outer side, while reducing unnecessary cold bridges. In the research of wall heat storage and insulation, Bao Encai and others designed the solidified sand passive heat storage wall in Wuhai desert area, Inner Mongolia. Porous brick was used as insulation layer on the outside and solidified sand was used as heat storage layer on the inside. The test showed that the indoor temperature could reach 13.7℃ in sunny days. Ma Yuehong etc. designed a wheat shell mortar block composite wall in northern Xinjiang, in which quicklime is filled in mortar blocks as a heat storage layer and slag bags are stacked outdoors as an insulation layer. The hollow block wall designed by Zhao Peng, etc. in the Gobi area of Gansu province, uses 100mm thick benzene board as insulation layer on the outside and sand and hollow block brick as heat storage layer on the inside. The test shows that the average temperature in winter is above 10℃ at night, and Chai Regeneration, etc. also use sand and gravel as insulation layer and heat storage layer of the wall in the Gobi area of Gansu province. In terms of reducing cold bridges, Yan Junyue etc. designed a light and simplified assembled back wall, which not only improved the thermal resistance of the wall, but also improved the sealing property of the wall by sticking polystyrene board on the outside of the back wall; Wu Letian etc. set reinforced concrete ring beam above the foundation of greenhouse wall, and used trapezoidal brick stamping just above the ring beam to support the back roof, which solved the problem that cracks and foundation subsidence are easy to occur in greenhouses in Hotian, Xinjiang, thus affecting the thermal insulation of greenhouses.

02 Choose suitable heat storage and insulation materials.

The heat storage and insulation effect of the wall depends first on the choice of materials. In the northwest desert, Gobi, sandy land and other areas, according to the site conditions, researchers took local materials and made bold attempts to design many different kinds of back walls of solar greenhouses. For example, when Zhang Guosen and others built greenhouses in sand and gravel fields in Gansu, sand and gravel were used as heat storage and insulation layers of walls; According to the characteristics of Gobi and desert in northwest China, Zhao Peng designed a kind of hollow block wall with sandstone and hollow block as materials. The test shows that the average indoor night temperature is above 10℃. In view of the scarcity of building materials such as bricks and clay in the Gobi region of northwest China, Zhou Changji and others found that the local greenhouses usually use pebbles as wall materials when investigating solar greenhouses in the Gobi region of Kizilsu Kirgiz, Xinjiang. In view of the thermal performance and mechanical strength of pebble, the greenhouse built with pebble has good performance in terms of heat preservation, heat storage and load bearing. Similarly, Zhang Yong, etc. also use pebbles as the main material of the wall, and designed an independent heat storage pebble back wall in Shanxi and other places. The test shows that the heat storage effect is good. Zhang etc. designed a kind of sandstone wall according to the characteristics of northwest Gobi area, which can raise the indoor temperature by 2.5℃. In addition, Ma Yuehong and others tested the heat storage capacity of block-filled sand wall, block wall and brick wall in Hotian, Xinjiang. The results showed that the block-filled sand wall had the largest heat storage capacity. In addition, in order to improve the heat storage performance of the wall, researchers actively develop new heat storage materials and technologies. For example, Bao Encai proposed a phase change curing agent material, which can be used to improve the heat storage capacity of the back wall of solar greenhouse in northwest non-cultivated areas. As the exploration of local materials, haystack, slag, benzene board and straw are also used as wall materials, but these materials usually only have the function of heat preservation and no heat storage capacity. Generally speaking, the walls filled with gravel and blocks have good heat storage and insulation capacity.

03 Appropriately increase the wall thickness

Usually, thermal resistance is an important index to measure the thermal insulation performance of the wall, and the factor that affects thermal resistance is the thickness of the material layer besides the thermal conductivity of the material. Therefore, on the basis of selecting appropriate thermal insulation materials, appropriately increasing the thickness of the wall can increase the overall thermal resistance of the wall and reduce the heat loss through the wall, thus increasing the thermal insulation and heat storage capacity of the wall and the whole greenhouse. For example, in Gansu and other areas, the average thickness of sandbag wall in Zhangye City is 2.6m, while that of mortar masonry wall in Jiuquan City is 3.7m. The thicker the wall, the greater its thermal insulation and heat storage capacity. However, too thick walls will increase the land occupation and the cost of greenhouse construction. Therefore, from the perspective of improving the thermal insulation capacity, we should also give priority to selecting high thermal insulation materials with low thermal conductivity, such as polystyrene, polyurethane and other materials, and then increase the thickness appropriately.

Reasonable design of rear roof

For the design of the rear roof, the main consideration is not to cause the influence of shading and improve the thermal insulation capacity. In order to reduce the influence of shading on the rear roof, the setting of its inclination angle is mainly based on the fact that the rear roof can receive direct sunlight during the daytime when crops are planted and produced. Therefore, the elevation angle of the rear roof is generally chosen to be better than the local solar altitude angle of the winter solstice of 7°~8°. For example, Zhang Caihong and others think that when building solar greenhouses in Gobi and saline-alkali land areas in Xinjiang, the projected length of the back roof is 1.6m, so the inclination angle of the back roof is 40°in southern Xinjiang and 45° in northern Xinjiang. Chen Wei-Qian and others think that the rear roof of the solar greenhouse in Jiuquan Gobi area should be inclined at 40°. For the thermal insulation of the rear roof, the thermal insulation capacity should be ensured mainly in the selection of thermal insulation materials, the necessary thickness design and the reasonable lap joint of thermal insulation materials during construction.

Reduce soil heat loss

During the winter night, because the temperature of indoor soil is higher than that of outdoor soil, the heat of indoor soil will be transferred to outdoor by heat conduction, causing the loss of greenhouse heat. There are several ways to reduce soil heat loss.

01 soil insulation

The ground sinks properly, avoiding the frozen soil layer, and using the soil for heat preservation. For example, the “1448 three-materials-one-body” solar greenhouse developed by Chai Regeneration and other non-cultivated land in Hexi Corridor was built by digging 1m down, effectively avoiding the frozen soil layer; According to the fact that the depth of frozen soil in Turpan area is 0.8m, Wang Huamin and others suggested digging 0.8m to improve the thermal insulation capacity of greenhouse. When Zhang Guosen, etc. built the back wall of the double-arch double-film digging solar greenhouse on non-arable land, the digging depth was 1m. The experiment showed that the lowest temperature at night was increased by 2~3℃ compared with the traditional second-generation solar greenhouse.

02 foundation cold protection

The main method is to dig a cold-proof ditch along the foundation part of the front roof, fill in thermal insulation materials, or continuously bury thermal insulation materials underground along the foundation wall part, all of which aim to reduce the heat loss caused by heat transfer through the soil at the boundary part of the greenhouse. The thermal insulation materials used are mainly based on the local conditions in northwest China, and can be obtained locally, such as hay, slag, rock wool, polystyrene board, corn straw, horse manure, fallen leaves, broken grass, sawdust, weeds, straw, etc.

03 mulch film

By covering the plastic film, sunlight can reach the soil through the plastic film during the day, and the soil absorbs the heat of the sun and heats up. Moreover, the plastic film can block the long-wave radiation reflected by the soil, thus reducing the radiation loss of the soil and increasing the heat storage of the soil. At night, plastic film can hinder the convective heat exchange between soil and indoor air, thus reducing the heat loss of soil. At the same time, plastic film can also reduce the latent heat loss caused by soil water evaporation. Wei Wenxiang covered the greenhouse with plastic film in Qinghai Plateau, and the experiment showed that the ground temperature could be raised by about 1℃.

Strengthen the thermal insulation performance of the front roof

The front roof of the greenhouse is the main heat dissipation surface, and the lost heat accounts for more than 75% of the total heat loss in the greenhouse. Therefore, strengthening the heat insulation capacity of the front roof of the greenhouse can effectively reduce the loss through the front roof and improve the winter temperature environment of the greenhouse. At present, there are three main measures to improve the thermal insulation capacity of the front roof.

01 Multi-layer transparent covering is adopted.

Structurally, using double-layer film or three-layer film as the light-transmitting surface of greenhouse can effectively improve the thermal insulation performance of greenhouse. For example, Zhang Guosen and others designed a double-arch double-film digging type solar greenhouse in the Gobi area of Jiuquan City. The outside of the front roof of the greenhouse is made of EVA film, and the inside of the greenhouse is made of PVC drip-free anti-aging film. Experiments show that compared with the traditional second-generation solar greenhouse, the thermal insulation effect is outstanding, and the lowest temperature at night rises by 2~3℃ on average. Similarly, Zhang Jingshe, etc. also designed a solar greenhouse with double film covering for the climatic characteristics of high latitude and severe cold areas, which significantly improved the thermal insulation of the greenhouse. Compared with the control greenhouse, the night temperature increased by 3℃. In addition, Wu Letian and others tried to use three layers of 0.1mm thick EVA film on the front roof of the solar greenhouse designed in Hetian desert area, Xinjiang. Multi-layer film can effectively reduce the heat loss of the front roof, but because the light transmittance of single-layer film is basically about 90%, multi-layer film will naturally lead to the attenuation of light transmittance. Therefore, when selecting multi-layer light transmittance covering, it is necessary to give due consideration to lighting conditions and lighting requirements of greenhouses.

02 Strengthen the night insulation of the front roof

Plastic film is used on the front roof to increase the light transmittance during the day, and it becomes the weakest place in the whole greenhouse at night. Therefore, covering the outer surface of the front roof with thick composite thermal insulation quilt is a necessary thermal insulation measure for solar greenhouses. For example, in Qinghai alpine region, Liu Yanjie and others used straw curtains and kraft paper as thermal insulation quilts for experiments. The test results showed that the lowest indoor temperature in greenhouse at night could reach above 7.7℃. Furthermore, Wei Wenxiang believes that the heat loss of greenhouse can be reduced by more than 90% by using double grass curtains or kraft paper outside grass curtains for thermal insulation in this area. In addition, Zou Ping, etc. used recycled fiber needled felt thermal insulation quilt in the solar greenhouse in the Gobi region of Xinjiang, and Chang Meimei, etc. used thermal insulation sandwich cotton thermal insulation quilt in the solar greenhouse in the Gobi region of Hexi Corridor. At present, there are many kinds of thermal insulation quilts used in solar greenhouses, but most of them are made of needled felt, glue-sprayed cotton, pearl cotton, etc., with waterproof or anti-aging surface layers on both sides. According to the thermal insulation mechanism of thermal insulation quilt, to improve its thermal insulation performance, we should start with improving its thermal resistance and reducing its heat transfer coefficient, and the main measures are to reduce the thermal conductivity of materials, increase the thickness of material layers or increase the number of material layers, etc. Therefore, at present, the core material of thermal insulation quilt with high thermal insulation performance is often made of multilayer composite materials. According to the test, the heat transfer coefficient of the thermal insulation quilt with high thermal insulation performance at present can reach 0.5W/(m2℃), which provides a better guarantee for the thermal insulation of greenhouses in cold areas in winter. Of course, the northwest area is windy and dusty, and the ultraviolet radiation is strong, so the thermal insulation surface layer should have good anti-aging performance.

03 Add an internal thermal insulation curtain.

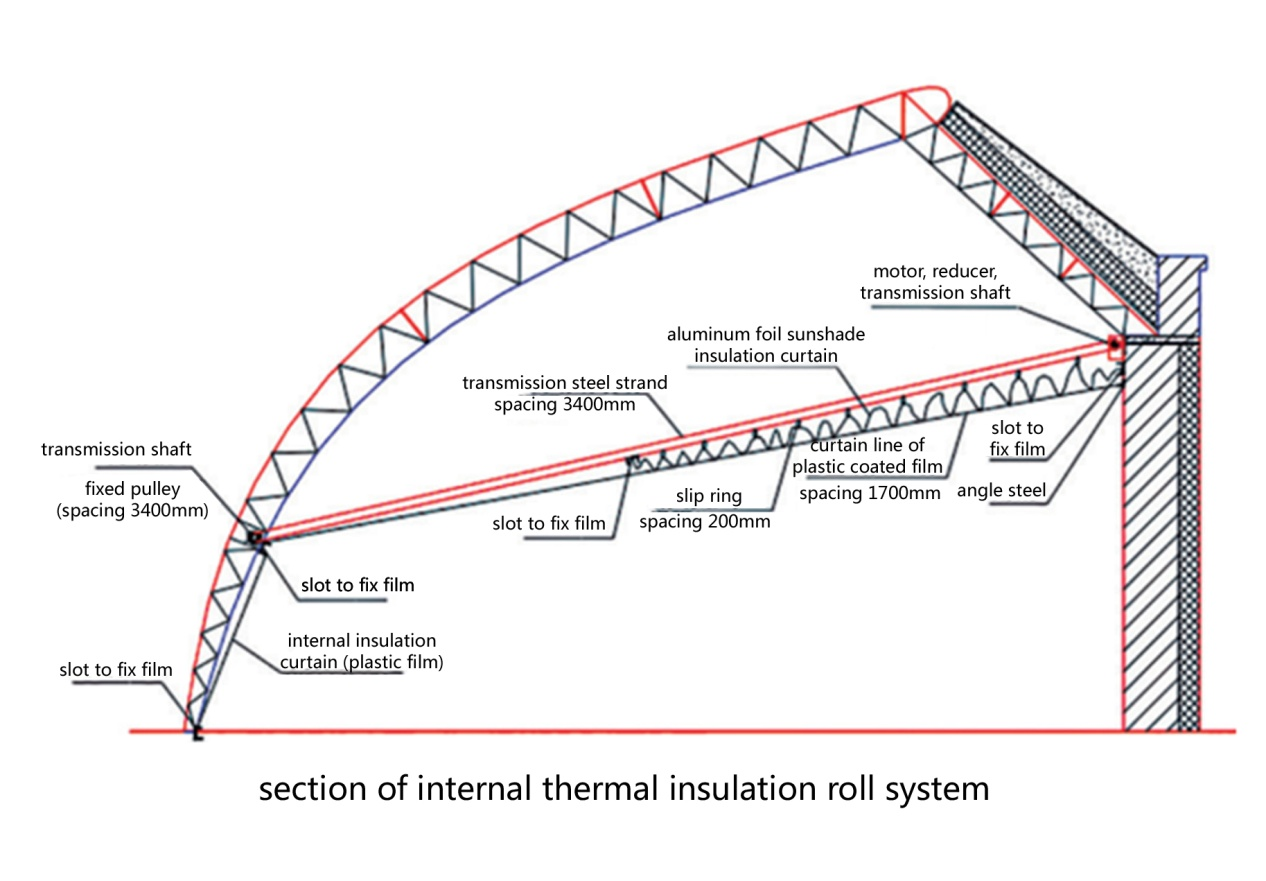

Although the front roof of the sunlight greenhouse is covered with an external thermal insulation quilt at night, as far as other structures of the whole greenhouse are concerned, the front roof is still a weak place for the whole greenhouse at night. Therefore, the project team of “Structure and Construction Technology of Greenhouse in Northwest Non-arable Land” designed a simple internal thermal insulation roll-up system (Figure 1), whose structure consists of a fixed internal thermal insulation curtain at the front foot and a movable internal thermal insulation curtain in the upper space. The upper movable thermal insulation curtain is opened and folded at the back wall of the greenhouse during the day, which does not affect the lighting of the greenhouse; The fixed thermal insulation quilt at the bottom plays the role of sealing at night. The internal insulation design is neat and easy to operate, and can also play the role of shading and cooling in summer.

Active warming technology

Because of the low temperature in winter in northwest China, if we only rely on the heat preservation and heat storage in greenhouses, we still can’t meet the requirements of crops’ overwintering production in some cold weather, so some active warming measures are also concerned.

Solar energy storage and heat release system

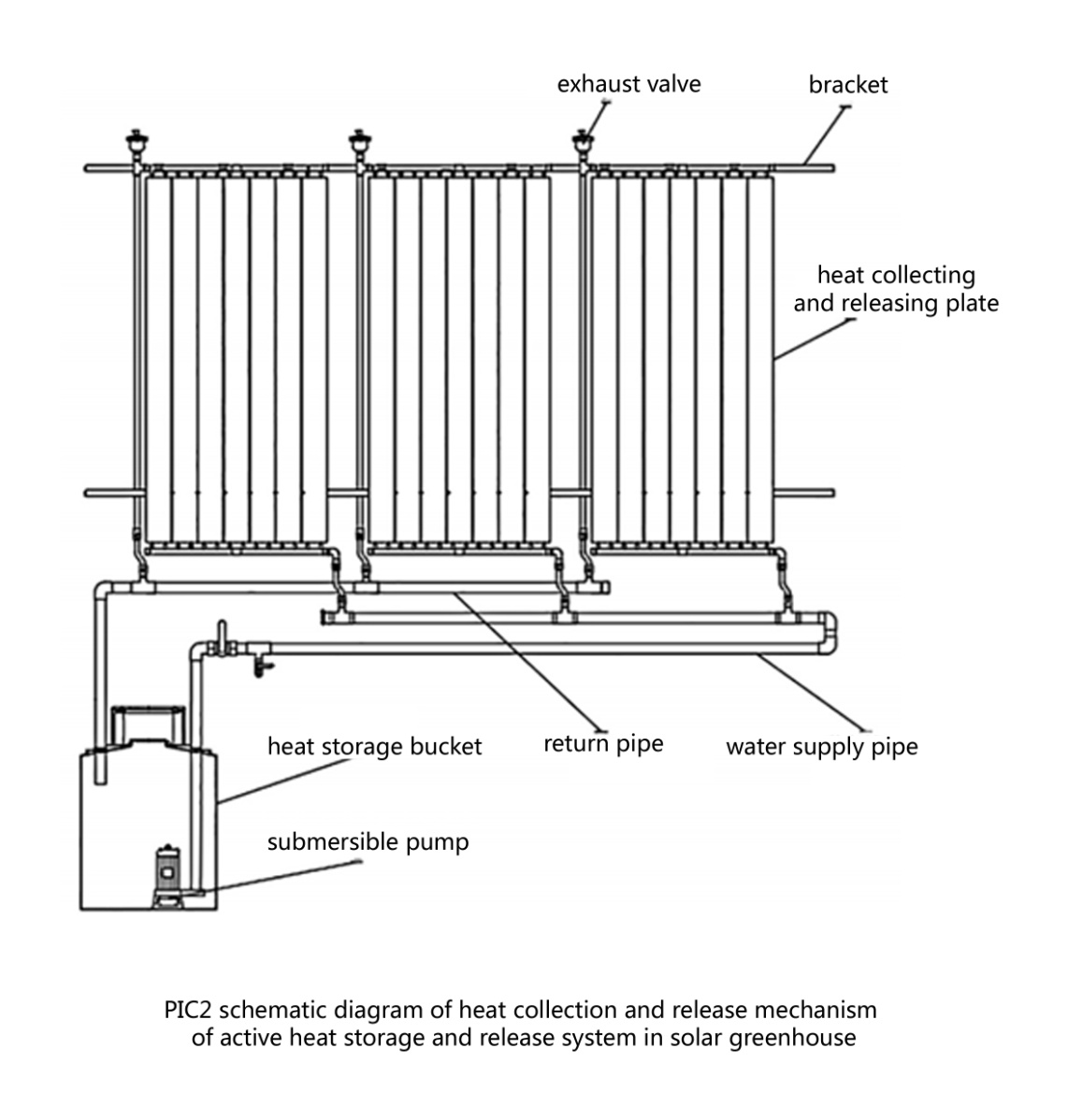

It is an important reason that the wall bears the functions of heat preservation, heat storage and load bearing, which leads to the high construction cost and low land utilization rate of solar greenhouses. Therefore, the simplification and assembly of solar greenhouses is bound to be an important development direction in the future. Among them, simplifying the function of the wall is to release the heat storage and release function of the wall, so that the back wall only bears the heat preservation function, which is an effective way to simplify the development. For example, Fang Hui’s active heat storage and release system (Figure 2) is widely used in non-cultivated areas such as Gansu, Ningxia and Xinjiang. Its heat collection device is hung on the north wall. During the day, the heat collected by the heat collection device is stored in the heat storage body through the circulation of the heat storage medium, and at night, the heat is released and heated by the circulation of the heat storage medium, thus realizing the heat transfer in time and space. Experiments show that the minimum temperature in the greenhouse can be raised by 3~5℃ by using this device. Wang Zhiwei etc. put forward a water curtain heating system for solar greenhouse in southern Xinjiang desert area, which can increase the temperature of greenhouse by 2.1℃ at night.

In addition, Bao Encai etc. designed an active heat storage circulation system for the north wall. During the daytime, through the circulation of axial fans, indoor hot air flows through the heat transfer duct embedded in the north wall, and the heat transfer duct exchanges heat with the heat storage layer inside the wall, which significantly improves the heat storage capacity of the wall. In addition, the solar phase-change heat storage system designed by Yan Yantao etc. stores heat in the phase-change materials through solar collectors during the daytime, and then dissipates the heat into indoor air through air circulation at night, which can increase the average temperature by 2.0℃ at night. The above solar energy utilization technologies and equipment have the characteristics of economy, energy saving and low carbon. After optimization and improvement, they should have a good application prospect in the areas with abundant solar energy resources in northwest China.

Other auxiliary heating technologies

01 biomass energy heating

The bedding, straw, cow dung, sheep dung and poultry dung are mixed with biological bacteria and buried in the soil in the greenhouse. A lot of heat is generated during the fermentation process, and a lot of beneficial strains, organic matter and CO2 are generated during the fermentation process. Beneficial strains can inhibit and kill a variety of germs, and can reduce the occurrence of greenhouse diseases and pests; Organic matter can become fertilizer for crops; The CO2 produced can enhance the photosynthesis of crops. For example, Wei Wenxiang buried hot organic fertilizers such as horse manure, cow manure and sheep manure in indoor soil in the solar greenhouse in Qinghai Plateau, which effectively raised the ground temperature. In the solar greenhouse in Gansu desert area,Zhou Zhilong used straw and organic fertilizer to ferment between crops. The test showed that the temperature of the greenhouse could be increased by 2~3℃.

02 coal heating

There are artificial stove, energy-saving water heater and heating. For example, after investigation in Qinghai Plateau, Wei Wenxiang found that artificial furnace heating was mainly used locally. This heating method has the advantages of faster heating and obvious heating effect. However, harmful gases such as SO2, CO and H2S will be produced in the process of burning coal, so it is necessary to do a good job of discharging harmful gases.

03 electric heating

Use electric heating wire to heat the front roof of greenhouse, or use electric heater. The heating effect is remarkable, the use is safe, no pollutants are generated in the greenhouse, and the heating equipment is easy to control. Chen Weiqian and others think that the problem of freezing damage in winter in Jiuquan area hinders the development of local Gobi agriculture, and electric heating elements can be used to heat the greenhouse. However, due to the use of high-quality electric energy resources, the energy consumption is high and the cost is high. It is suggested that it should be used as a temporary means of emergency heating in extreme cold weather.

Environmental management measures

In the process of production and use of greenhouse, the complete equipment and normal operation can not effectively ensure that its thermal environment meets the design requirements. In fact, the use and management of equipment often play a key role in the formation and maintenance of the thermal environment, the most important of which is the daily management of thermal insulation quilt and vent.

Management of thermal insulation quilt

Thermal insulation quilt is the key to the night thermal insulation of the front roof, so it is extremely important to refine its daily management and maintenance, especially the following problems should be paid attention to:①Choose the appropriate opening and closing time of thermal insulation quilt. The opening and closing time of the thermal insulation quilt not only affects the lighting time of the greenhouse, but also affects the heating process in the greenhouse. Opening and closing the thermal insulation quilt too early or too late is not conducive to the collection of heat. In the morning, if the quilt is uncovered too early, the indoor temperature will drop too much because of the low outdoor temperature and weak light. On the contrary, if the time of uncovering the quilt is too late, the time of receiving light in the greenhouse will be shortened, and the indoor temperature rise time will be delayed. In the afternoon, if the thermal insulation quilt is turned off too early, the indoor exposure time will be shortened, and the heat storage of indoor soil and walls will be reduced. On the contrary, if the heat preservation is turned off too late, the heat dissipation of the greenhouse will be increased due to the low outdoor temperature and weak light. Therefore, generally speaking, when the thermal insulation quilt is turned on in the morning, it is advisable for the temperature to rise after 1~2℃ drop, while when the thermal insulation quilt is turned off, it is advisable for the temperature to rise after 1~2℃ drop. ② When closing the thermal insulation quilt, pay attention to observe whether the thermal insulation quilt covers all the front roofs tightly, and adjust them in time if there is a gap. ③ After the thermal insulation quilt is completely put down, check whether the lower part has been compacted, so as to prevent the heat preservation effect from being lifted by the wind at night. ④ Check and maintain the thermal insulation quilt in time, especially when the thermal insulation quilt is damaged, repair or replace it in time. ⑤ Pay attention to the weather conditions in time. When there is rain or snow, cover the thermal insulation quilt in time and remove snow in time.

Management of vents

The purpose of ventilation in winter is to adjust the air temperature to avoid excessive temperature around noon; The second is to eliminate indoor moisture, reduce the air humidity in the greenhouse and control pests and diseases; The third is to increase indoor CO2 concentration and promote crop growth. However, ventilation and heat preservation are contradictory. If ventilation is not properly managed, it will probably lead to low temperature problems. Therefore, when and how long to open the vents need to be dynamically adjusted according to the environmental conditions of the greenhouse at any time. In the northwest non-cultivated areas, the management of greenhouse vents is mainly divided into two ways: manual operation and simple mechanical ventilation. However, the opening time and ventilation time of the vents are mainly based on people’s subjective judgment, so it may happen that the vents are opened too early or too late. To solve the above problems, Yin Yilei etc. designed a roof intelligent ventilation device, which can determine the opening time and the opening and closing size of ventilation holes according to the changes of indoor environment. With the deepening of the research on the law of environmental change and crop demand, as well as the popularization and progress of technologies and equipment such as environmental perception, information collection, analysis and control, the automation of ventilation management in solar greenhouses should be an important development direction in the future.

Other management measures

In the process of using various kinds of shed films, their light transmission capacity will gradually weaken, and the weakening speed is not only related to their own physical properties, but also related to the surrounding environment and management during use. In the process of use, the most important factor that leads to the decline of light transmission performance is the pollution of the film surface. Therefore, it is extremely important to conduct regular cleaning and cleaning when conditions permit. In addition, the enclosure structure of the greenhouse should be checked regularly. When there is a leak in the wall and front roof, it should be repaired in time to avoid the greenhouse being affected by cold air infiltration.

Existing problems and development direction

Researchers have explored and studied the heat preservation and storage technology, management technology and warming methods of greenhouses in northwest non-cultivated areas for many years, which basically realized the overwintering production of vegetables, greatly improved the greenhouse’s ability to resist low-temperature chilling injury, and basically realized the overwintering production of vegetables. It has made a historic contribution to alleviating the contradiction between food and vegetables competing for land in China. However, there are still the following problems in the temperature guarantee technology in northwest China.

Greenhouse types to be upgraded

At present, the types of greenhouses are still the common ones built in the late 20th century and early this century, with simple structure, unreasonable design, poor ability to maintain greenhouse thermal environment and resist natural disasters, and lack of standardization. Therefore, in the future greenhouse design, the shape and inclination of the front roof, the azimuth angle of the greenhouse, the height of the back wall, the sinking depth of the greenhouse, etc. should be standardized by fully combining the local geographic latitude and climate characteristics. At the same time, only one crop can be planted in a greenhouse as far as possible, so that standardized greenhouse matching can be carried out according to the light and temperature requirements of the planted crops.

Greenhouse scale is relatively small.

If the greenhouse scale is too small, it will affect the stability of the greenhouse thermal environment and the development of mechanization. With the gradual increase of labor cost, mechanization development is an important direction in the future. Therefore, in the future, we should base ourselves on the local development level, take into account the needs of mechanization development, rationally design the interior space and layout of greenhouses, speed up the research and development of agricultural equipment suitable for local areas, and improve the mechanization rate of greenhouse production. At the same time, according to the needs of crops and cultivation patterns, the relevant equipment should be matched with standards, and the integrated research and development, innovation and popularization of ventilation, humidity reduction, heat preservation and heating equipment should be promoted.

The thickness of walls such as sand and hollow blocks is still thick.

If the wall is too thick, although the insulation effect is good, it will reduce the utilization rate of soil, increase the cost and the difficulty of construction. Therefore, in the future development, on the one hand, the wall thickness can be scientifically optimized according to the local climatic conditions; On the other hand, we should promote the light and simplified development of the back wall, so that the back wall of the greenhouse only retains the function of heat preservation, use solar collectors and other equipment to replace the heat storage and release of the wall. Solar collectors have the characteristics of high heat collection efficiency, strong heat collection capacity, energy saving, low carbon and so on, and most of them can realize active regulation and control, and can carry out targeted exothermic heating according to the environmental requirements of greenhouse at night, with higher efficiency of heat utilization.

Special thermal insulation quilt needs to be developed.

The front roof is the main body of heat dissipation in greenhouse, and the thermal insulation performance of thermal insulation quilt directly affects the indoor thermal environment. At present, the greenhouse temperature environment in some areas is not good, partly because the thermal insulation quilt is too thin, and the thermal insulation performance of materials is insufficient. At the same time, the thermal insulation quilt still has some problems, such as poor waterproof and skiing ability, easy aging of the surface and core materials, etc. Therefore, in the future, appropriate thermal insulation materials should be scientifically selected according to local climatic characteristics and requirements, and special thermal insulation quilt products suitable for local use and popularization should be designed and developed.

END

Cited information

Luo Ganliang, Cheng Jieyu, Wang Pingzhi, etc. Research status of environmental temperature guarantee technology of solar greenhouse in northwest non-cultivated land [J]. Agricultural Engineering Technology, 2022,42(28):12-20.

Post time: Jan-09-2023