Author: Changji Zhou, Hongbo Li, etc.

Article Source: Greenhouse Horticulture Agricultural Engineering Technology

This is the experimental base of the Haidian District Agricultural Science Institute, as well as the Haidian Agricultural High-tech Exhibition and Science Park. In 2017, the author led the introduction of a multi-span plastic film test greenhouse with high thermal insulation from South Korea. At present, Director Zheng has transformed it into a strawberry production greenhouse integrating technology display, sightseeing and picking, leisure and entertainment. It is named “5G Cloud Strawberry”, and I will take you to experience it together.

Strawberry Greenhouse Planting and Its Space Utilization

Liftable strawberry shelf and hanging system

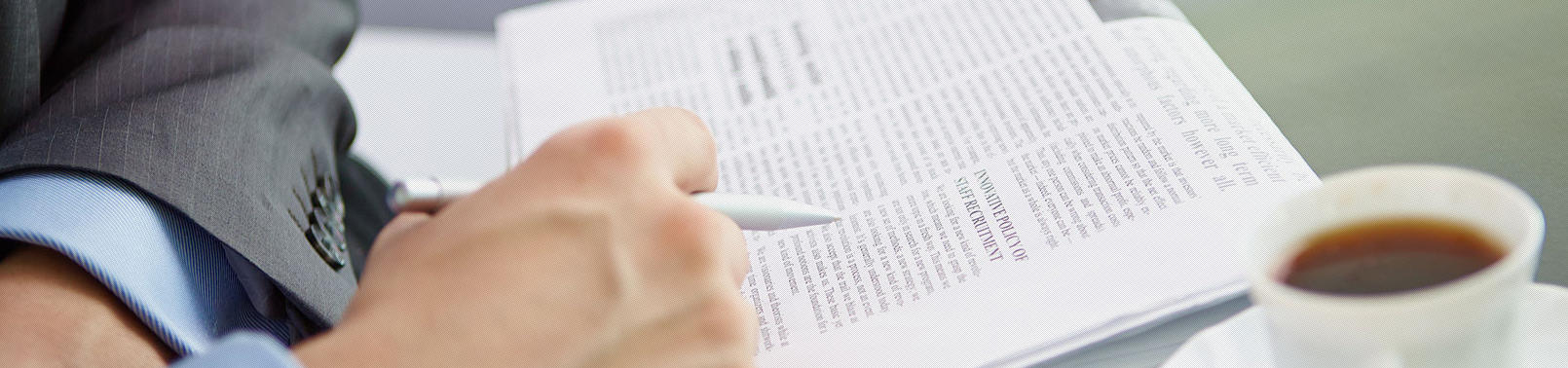

Cultivation slot and cultivation method

The cultivation slot concentrates the water supply and drainage at the bottom of the cultivation slot, and an edge is raised outward in the middle of the bottom surface of the cultivation slot in the long direction (from the inside of the cultivation slot, a bottom groove is formed at the bottom). The main water supply to the cultivation slot is directly laid in this bottom groove, and the water leached from the cultivation medium is also collected into this groove uniformly, and finally discharged from one end of the cultivation slot.

The advantages of planting strawberries with a cultivation pot are that the bottom of the cultivation pot is separated from the bottom surface of the cultivation slot, and a high aquifer will not be formed in the lower part of the substrate, and the overall ventilation of the substrate is improved; It will spread with the flow of irrigation water; thirdly, there will be no leakage when the substrate is installed in the cultivation pot, and the cultivation shelf is neat and beautiful as a whole. The disadvantage of this approach is mainly that drip irrigation and cultivation pot planting increase the investment in equipment construction.

Growing slots and pots

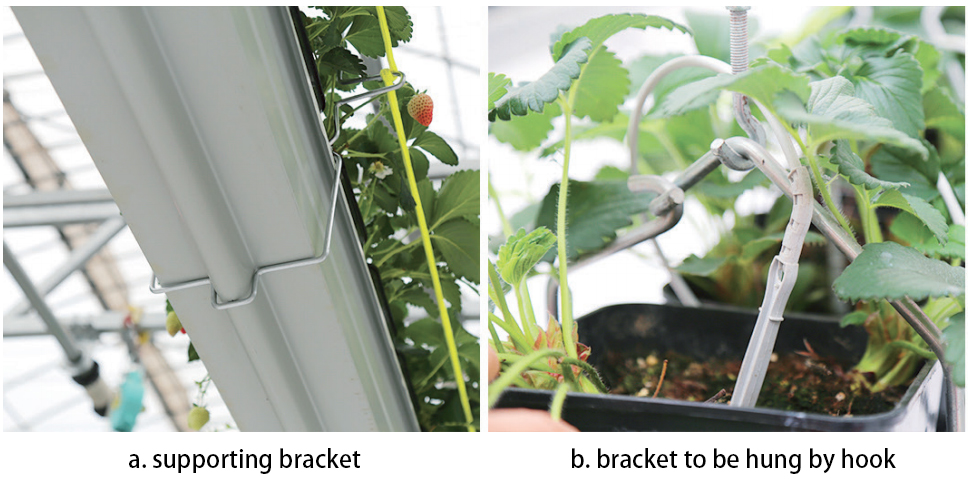

Cultivation rack hanging and lifting system

The hanging and lifting system of the cultivation shelf is basically the same as that of the traditional strawberry lifting cultivation shelf. The hanging buckle of the cultivation slot surrounds the cultivation slot, and connects the hanging buckle and the reversing wheel with an adjustable-length flower basket screw (used to adjust the consistency of the installation height of the cultivation slot). On the lower chord, the other end is wound on the wheel connected to the drive shaft of the motor reducer.

Cultivation shelf hanging system

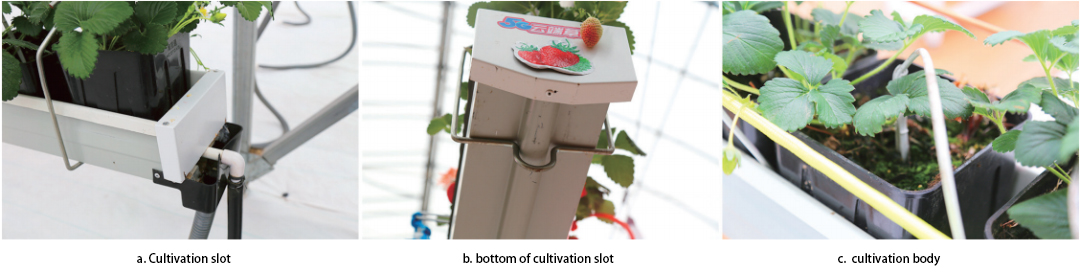

On the basis of the overall universal hanger system, in order to meet the needs of the special cross-sectional shape of the cultivation slot and the needs of sightseeing display, some personalized accessories and facilities are also innovatively designed here.

(1) Cultivation shelf hanger. The hanging buckle of the cultivation shelf is firstly a closed-loop buckle, which is formed by bending and welding a steel wire. The cross-section of each part of the hanging buckle is the same, and the mechanical properties are consistent; The bottom section of the slot also adopts the corresponding semi-circular bending; the third is to fold the middle of the buckle into an acute angle, and the upper buckle is directly hooked at the bending point, which not only ensures the stable center of gravity of the cultivation slot, but also does not occur lateral deformation, and it also ensures that the buckle is hooked reliably and will not slip and dislocate.

Cultivation shelf buckle

(2) Safety hanging rope. On the basis of the traditional hanging system, an additional set of safety hanging system is installed every 6m along the length of the cultivation slot. The requirements for the additional safety hanging system are, first, to run synchronously with the drive hanging system; second, to have sufficient bearing capacity. In order to achieve the above functional requirements, a set of spring winding device hanging system is designed and selected to retract the hanging rope of the cultivation slot. The spring winder is arranged in parallel with the driving hanging rope, and is hung and fixed on the lower chord of the greenhouse truss.

Additional Safety Suspension System

Auxiliary production equipment of cultivation rack

(1) Plant carding system. The plant carding system mentioned here is mainly composed of two parts: a plant carding bracket and a colored silver rope. Among them, the plant carding bracket is an assembly composed of a partially bent and overall U-shaped fold card and a U-shaped card with double limit rods. The bottom and lower half of the U-shaped folded card match the external dimensions of the cultivation slot, and surround the cultivation slot from the bottom; after its double branches exceed the open position of the cultivation slot, make a bend to connect the double limit rods, and also it plays the role of restricting the deformation of the opening of the cultivation slot; it is a small U-shaped bend that is convex upward, which is used to fix the fruit leaf separation rope of strawberries; the top part of the U-shaped card is a W-shaped bend for fixing strawberry branches and leaves combing rope. The U-shaped folded card and the double limit rod are all formed by bending galvanized steel wire.

The fruit leaf separation rope is used to gather the branches and leaves of the strawberry within the opening width of the cultivation slot, and hang the strawberry fruit outside the cultivation slot, which is not only convenient for fruit picking, but also protect the strawberry from the direct spraying of liquid medicine, and can improve the ornamental quality of strawberry planting.

Plant carding system

(2) the moving yellow rack. A movable yellow rack is specially designed, that is, a vertical pole for hanging yellow and blue boards is welded on a tripod, which can be directly placed on the greenhouse floor and can be moved at any time.

(3) Self-driving plant protection vehicle. This vehicle can be equipped with a plant protection sprayer, that is, an automatic driving sprayer, which can carry out plant protection operations without operators indoors according to the computer-planned path, which can protect the health of greenhouse operators.

equipment of plant protection

Nutrient Supply and Irrigation System

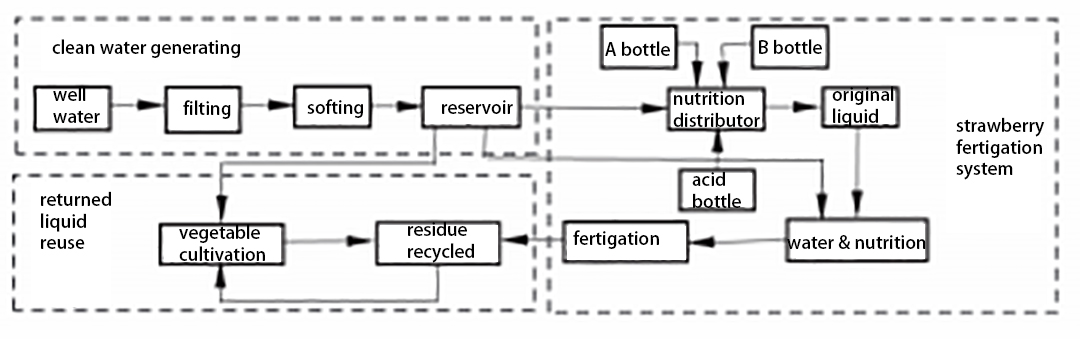

The nutrient solution supply and irrigation system of this project is divided into 3 parts: one is the clear water preparation part; the second is the strawberry irrigation and fertilization system; the third is the liquid recycling system for strawberry cultivation. The equipment for the preparation of clear water and the system of nutrient solution are collectively referred to as the irrigation head, and the equipment for supplying and returning water to the crops is referred to as the irrigation equipment.

Nutrient Supply and Irrigation System

Irrigation front

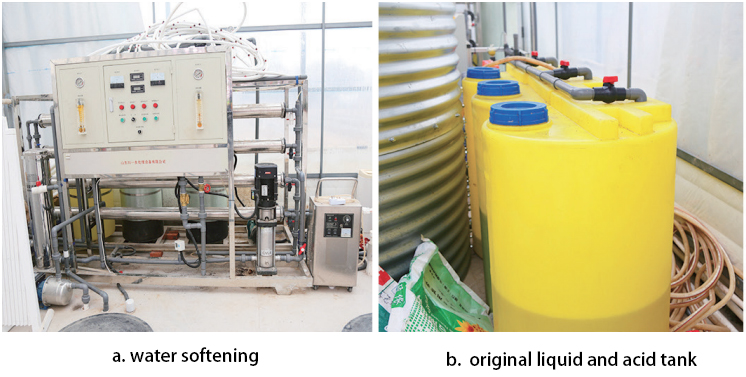

The clean water preparation equipment should generally be equipped with sand and gravel filters to remove sand, and water softening equipment to remove salt. Filtered and softened clean water is stored in a storage tank for later use.

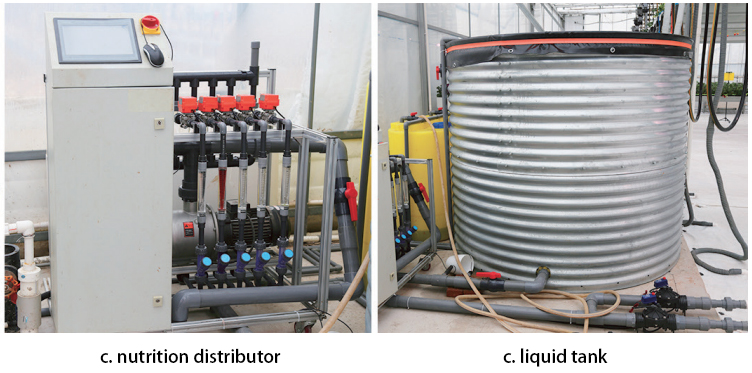

The configuration equipment of nutrient solution generally includes three raw material tanks for A and B fertilizers, and an acid tank for adjusting pH, and a set of fertilizer mixers. During operation, the stock solution in tanks A, B and acid tank is configured and mixed in proportion by the fertilizer machine according to the set formula to form raw nutrient solution, and the raw nutrient solution configured by the fertilizer machine is stored in the stock solution storage tank for stand-by.

Nutrient solution preparation equipment

Water supply and return system for strawberry planting

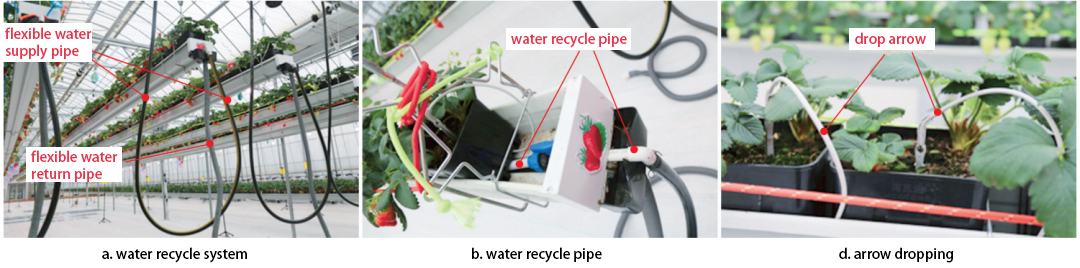

The water supply and return system for strawberry planting adopts the method of centralized water supply and return at one end of the cultivation slot. Since the cultivation slot adopts a lifting and hanging method, two forms are used for the water supply and return pipes of the cultivation slot: one is a fixed rigid pipe; the other is a flexible pipe that moves up and down with the cultivation slot. During irrigation and fertilization, the liquid supply from the clear water tank and the raw liquid storage tank is sent to the water and fertilizer integrated machine for mixing according to the set ratio (a simple method can use a proportional fertilizer applicator, such as a Venturi, etc., which can be powered or not driven force) and then sent to the top of the cultivation hanger through the main water supply pipe (the main water supply pipe is installed on the greenhouse truss along the span of the greenhouse), and the flexible rubber hose leads the irrigation water from the main water supply pipe to the end of each cultivation rack, then connect to the water supply branch pipe set in the cultivation slot. The water supply branch pipes in the cultivation slot are arranged along the length of the cultivation slot, and along the way, the drip pipes are connected according to the arrangement position of the cultivation pot, and the nutrients are dropped into the medium of the cultivation pot through the drip pipes. The excess nutrient solution exuded from the substrate is drained into the cultivation slot through the drain hole at the bottom of the cultivation pot and collected into the drainage ditch at the bottom of the cultivation slot. Adjust the installation height of the cultivation slot to form a constant flow from one end to the other. On sloped slopes, the irrigation return liquid collected from the bottom of the slot will eventually collect into the end of the slot. An opening is arranged at the end of the cultivation slot to connect the connecting tank of return liquid, and a liquid return pipe is connected under the collecting tank, and the collected return liquid is finally collected and discharged into the liquid return tank.

Irrigation water supply and return system

Utilization of return liquid

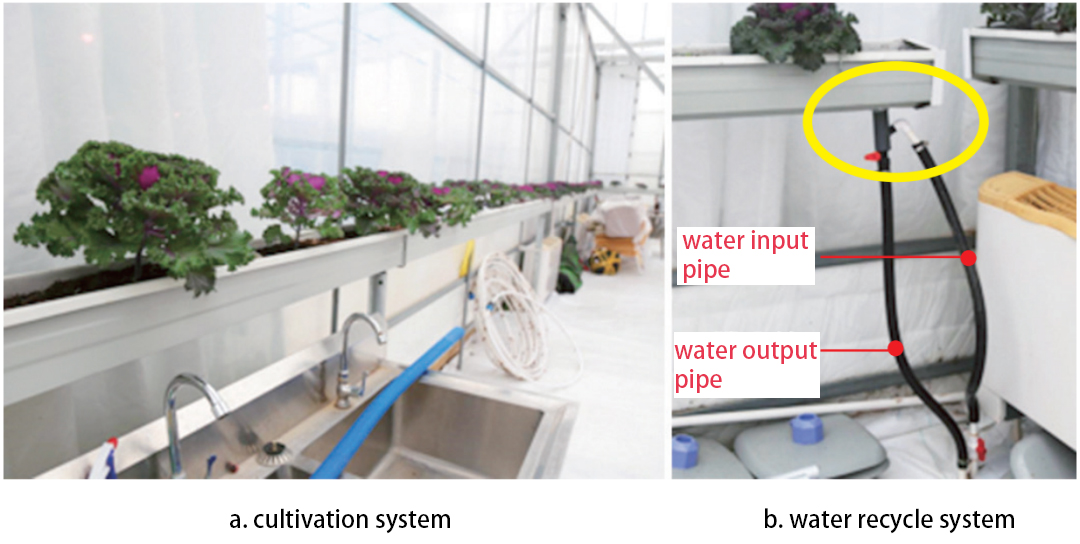

This greenhouse irrigation return liquid does not use the closed-loop circulation operation of the strawberry production system, but collects the return liquid from the strawberry planting slot and directly uses it for the planting of ornamental vegetables. The same fixed height cultivation slot as strawberry cultivation is set on the four peripheral walls of the greenhouse, and the cultivation slot is filled with cultivation substrate to grow ornamental vegetables. The return liquid of strawberries is directly irrigated to these ornamental vegetables, uses clean water in the storage tank for daily irrigation. In addition, the water supply and return pipes of the cultivation slot are combined into one in the design of the water supply and return pipes. The tidal irrigation mode is adopted in the cultivation slot. During the water supply period, the valve of the water supply pipe is opened and the valve of the return pipe is closed. The pipe valve is closed and the drain valve is open. This irrigation method saves the irrigation water supply branch pipes and sub-pipes in the cultivation slot, saves investment, and basically has no impact on the production of ornamental vegetables.

Growing Ornamental Vegetables Using return Liquid

Greenhouse and supporting facilities

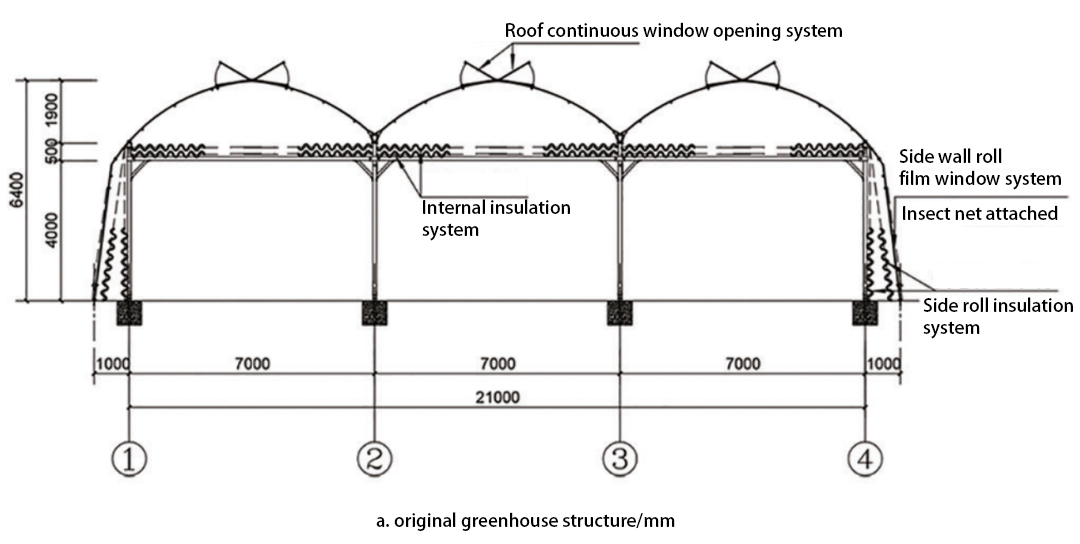

The greenhouse was imported from South Korea in full in 2017. Its length is 47m, width is 23m, with a total area of 1081 m2 . The span of the greenhouse is 7m, the bay is 3m, the eaves height is 4.5m, and the ridge height is 6.4m, with a total of 3 spans and 15 bays. In order to enhance the thermal insulation of the greenhouse, a 1m wide thermal insulation corridor is set around the greenhouse, and an indoor double-layer thermal insulation curtain is designed. During the structural transformation, the horizontal chords on the top of the columns between the spans of the original greenhouse were replaced with truss beams.

Greenhouse structure

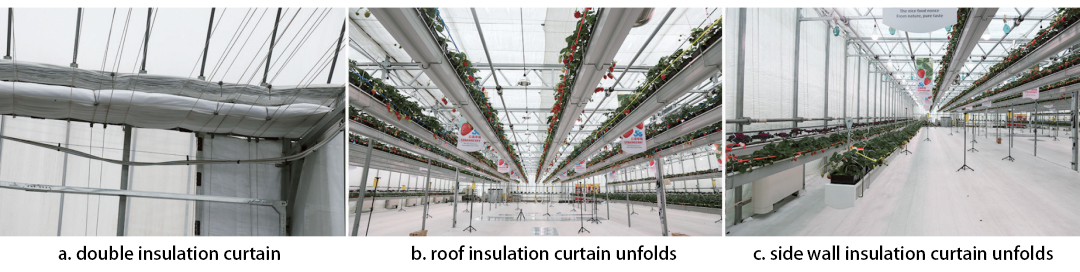

The renovation of the greenhouse thermal insulation system retains the original design of the thermal insulation system of the roof and wall with double internal thermal insulation. However, after 3 years of operation, the original insulation shade net was partially aged and damaged. In the renovation of the greenhouse, all insulation curtains were updated and replaced with acrylic cotton insulation quilts, which are lighter and more thermally insulated, domestically made. From the actual operation, the joints overlap between the roof insulation curtains, the wall insulation quilt and the roof insulation quilt overlap, and the entire insulation system is tightly sealed.

Greenhouse Insulation System

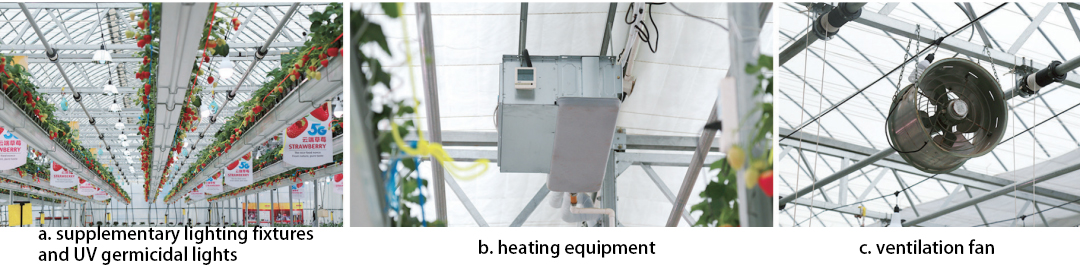

In order to ensure the light requirements for crop growth, a supplementary light system was added in the renovation of the greenhouse. The supplementary light adopts biological effect LED lighting system, each LED grow light has a power of 50 W, arrange 2 columns per span. The space of each column lights is 3m. The total light power is 4.5 kW, equivalent to 4.61 W/m2 per unit area. The light intensity of 1m height can reach more than 2000 lx.

At the same time of installing the plnat supplementary lights, a row of UVB lghts are also installed on each span with a spacing of 2 m, which are mainly used for irregular disinfection of the air in the greenhouse. The power of a single UVB light is 40 W, and the total installed power is 4.36 kW, equivalent to 4.47 W/m 2 per unit area .

The greenhouse heating system uses a more environmentally clean energy air source heat pump, which sends hot air into the greenhouse through a heat exchanger. The total power of the air source heat pump in the greenhouse is 210kW, and 38 units of heat exchange fans are evenly distributed in the room. The heat dissipation of each fan is 5.5kw, which can ensure the air temperature in the greenhouse above 5℃ under the outdoor temperature of -15℃ on the coldest day in Beijing, thus ensuring the safe production of strawberry in the greenhouse.

In order to ensure the uniformity of air temperature and humidity in the greenhouse and to form certain air movement indoors, the greenhouse is also equipped with a horizontal air circulation fan. The circulating fans are arranged in the middle of the greenhouse span with an interval of 18 m, and the power of a single fan is 0.12 kW.

Greenhouse supporting environmental control equipment

Citation information:

Changji Zhou, Hongbo, Li, He Zheng, etc. Dr. Zhou inspected Shiling (One Hundred and Twenty Six) sightseeing-type liftable strawberry hanger and supporting facilities and equipment[J]. Agricultural Engineering Technology,2022,42(7):36-42.

Post time: Aug-01-2022