[Abstract]Currently, home planting devices usually adopt an integrated design, which brings a lot of inconvenience to movement and loading and unloading. Based on the characteristics of the living space of urban residents and the design goal of family plant production, this article proposes a new type of prefabricated family planting device design. The device consists of four parts: a support system, a cultivation system, a water and fertilizer system, and a light supplement system (mostly, LED grow lights). It has a small footprint, high space utilization, novel structure, convenient disassembly and assembly, low cost, and strong practicability. It can meet the needs of urban residents about lettuce for celery, fast vegetable, nourishing cabbage and begonia fimbristipula. After small-scale modification, it can also be used for plant scientific experiment research

Overall Design of Cultivation Equipment

Design Principles

The prefabricated cultivation device is mainly oriented to urban residents. The team fully investigated the characteristics of the living space of urban residents. The area is small and the space utilization rate is high; the structure is novel and beautiful; it is convenient to disassemble and assemble, simple and easy to learn; it has low cost and strong practicability. These four principles run through the entire design process, and strive to achieve the ultimate goal of harmonizing with the home environment, beautiful and decent structure, and economical and practical use value.

Materials to be used

The support frame is purchased from the market’s multi-layer shelf product, 1.5 m long, 0.6 m wide, and 2.0 m high. The material is steel, sprayed and rust-proofed, and the four corners of the support frame are welded with brake universal wheels; the ribbed plate is selected to strengthen the support frame layer plate which is made of 2 mm thick steel plate with spray-plastic anti-rust treatment, two pieces per layer. The cultivation trough is made of open-cap PVC hydroponic square tube, 10 cm×10 cm. The material is hard PVC board, with thickness of 2.4 mm. The diameter of cultivation holes is 5 cm, and the spacing of cultivation holes is 10 cm. The nutrient solution tank or water tank is made of a plastic box with a wall thickness of 7 mm, with a length of 120 cm, a width of 50 cm, and a height of 28 cm.

Cultivation Device Structure Design

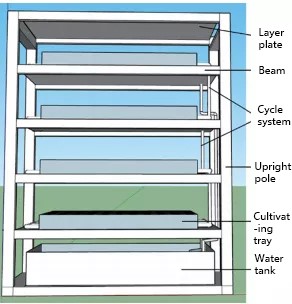

According to the overall design plan, the prefabricated family cultivation device consists of four parts: a support system, a cultivation system, a water and fertilizer system, and a light supplement system(mostly, LED grow lights). The distribution in the system is shown in Figure 1.

Figure 1, the distribution in the system is shown in.

Support system design

The support system of the prefabricated family cultivation device is composed of a upright pole, a beam and a layer plate. The pole and the beam are inserted through the butterfly hole buckle, which is convenient to disassemble and assemble. The beam is equipped with a reinforced rib layer plate. The four corners of the cultivation frame are welded with universal wheels with brakes to increase the flexibility of the movement of the cultivation device.

Cultivation system design

The cultivation tank is a 10 cm×10 cm hydroponic square tube with an open cover design, which is easy to clean, and can be used for nutrient solution cultivation, substrate cultivation or soil cultivation. In nutrient solution cultivation, the planting basket is placed in the planting hole, and the seedlings are fixed with a sponge of corresponding specifications. When the substrate or soil is cultivated, sponge or gauze is stuffed into the connecting holes at both ends of the cultivation trough to prevent the substrate or soil from blocking the drainage system. The two ends of the cultivation tank are connected to the circulation system by a rubber hose with an inner diameter of 30 mm, which effectively avoids the defects of structural solidification caused by PVC glue bonding, which is not conducive to movement.

Water and Fertilizer Circulation System Design

In nutrient solution cultivation, use an adjustable pump to add the nutrient solution to the top-level cultivation tank, and control the flow direction of the nutrient solution through the inner plug of the PVC pipe. In order to avoid the uneven flow of the nutrient solution, the nutrient solution in the same-layer cultivation tank adopts a unidirectional “S-shaped” flow method . In order to increase the oxygen content of the nutrient solution, when the lowest layer of nutrient solution flows out, a certain gap is designed between the water outlet and the liquid level of the water tank. In substrate or soil cultivation, the water tank is placed on the top layer, and watering and fertilization are carried out through a drip irrigation system. The main pipe is a black PE pipe with a diameter of 32 mm and a wall thickness of 2.0 mm, and the branch pipe is a black PE pipe with a diameter of 16 mm and a wall thickness of 1.2 mm. Each branch pipe Install a valve for individual control. The drop arrow uses a pressure-compensated straight arrow dripper, 2 per hole, inserted into the root of the seedling in the cultivation hole. Excess water is collected through the drainage system, filtered and reused.

Light Supplement System

When the cultivation device is used for balcony production, the natural light from the balcony can be used without supplementary light or a small amount of supplementary light. When cultivating in the living room, it is necessary to carry out the supplementary lighting design. The lighting fixture is a 1.2 m long LED grow light, and the light time is controlled by an automatic timer. The light time is set to 14 h, and the non- supplementary light time is 10 h. There are 4 LED lights in each layer, which are installed at the bottom of the layer. The four tubes on the same layer are connected in series, and the layers are connected in parallel. According to the different lighting needs of different plants, LED light with different spectrum can be selected.

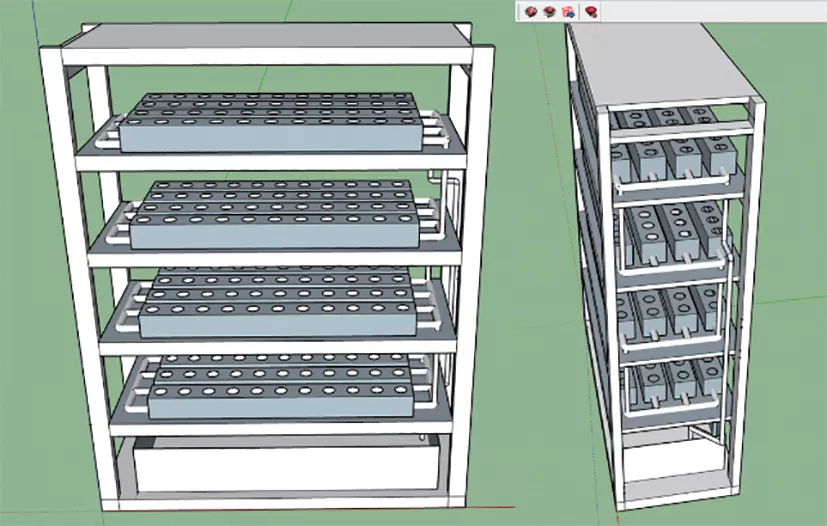

Device Assembling

The prefabricated home cultivation device is simple in structure (Figure 2) and the assembling process is simple. In the first step, after determining the height of each layer according to the height of the cultivated crops, insert the beam into the butterfly hole of the upright pole to build the device skeleton; in the second step, fix the LED grow light tube on the reinforcing rib on the back of the layer, and place the layer in the inner trough of the crossbeam of the cultivation frame; the third step, the cultivation trough and the water and fertilizer circulation system are connected by a rubber hose; the fourth step, install the LED tube, set the automatic timer, and place the water tank; the fifth step-system debugging, add water to the water tank After adjusting the pump head and flow, check the water and fertilizer circulation system and the connection of the cultivation tank for water leakage, power on and check the LED lights connection and the working condition of the automatic timer.

Figure 2, overall design of prefabricated cultivation device

Application and Evaluation

Cultivation Application

In 2019, the device will be used for small-scale indoor cultivation of vegetables such as lettuce, Chinese cabbage, and celery (Figure 3). In 2020, on the basis of summarizing the previous cultivating experience, the project team developed the organic substrate cultivation of the food and medicine homologous vegetable and the nutrient solution cultivation technology of Begonia fimbristipula hance, which enriched the home application examples of the device. In the past two years of cultivation and application, lettuce and fast vegetable can be harvested 25 days after cultivating at an indoor temperature of 20-25℃; celery needs to grow for 35-40 days; Begonia fimbristipula Hance and Chinese cabbage are perennial plants that can be harvested in multiple times; Begonia fimbristipula can harvest the top 10 cm stems and leaves in about 35 days, and the young stems and leaves can be harvested in about 45 days for growing cabbage. When harvested, the yield of lettuce and Chinese cabbage is 100~150 g per plant; the yield of white celery and red celery per plant is 100~120 g; the yield of Begonia fimbristipula Hance in the first harvest is low, 20-30 g per plant, and with the continuous germination of side branches, it can be harvested for the second time, with an interval of about 15 days and yields of 60-80 g per plant; the yield of the nourishing menu hole is 50-80 g, harvested once every 25 days, and can be harvested continuously.

Figure 3, Production application of prefabricated cultivation device

Application Effect

After more than a year of production and application, the device can make full use of the three-dimensional space of the room for small-scale production of a variety of crops. Its loading and unloading operations are simple and easy to learn, and no professional training is required. By adjusting the lift and flow of the water pump, the problem of excessive flow and overflow of nutrient solution in the cultivation tank can be avoided. The open cover design of the cultivation tank is not only easy to clean after use, but also easy to replace when the accessories are damaged. The cultivation tank is connected with the rubber hose of the water and fertilizer circulation system, which realizes the modular design of the cultivation tank and the water and fertilizer circulation system, and avoids the disadvantages of the integrated design in the traditional hydroponic device. In addition, the device can be used for scientific research under controllable temperature and humidity conditions in addition to household crop production. It not only saves test space, but also meets the requirements of the production environment, especially the consistency of the root growth environment. After simple improvement, the cultivation device can also meet the requirements of different treatment methods of the rhizosphere environment, and has been widely used in plant scientific experiments.

Article source: Wechat account of Agricultural Engineering Technology (greenhouse horticulture)

Reference information: Wang Fei,Wang Changyi,Shi Jingxuan,et al.Design and application of prefabricated household cultivation device[J].Agricultural Engineering Technology,2021,41(16):12-15.

Post time: Jan-14-2022